Melting and boiling points

Titanium has a high melting point of 1668℃ and an even higher boiling point of 3287℃. These high melting and boiling points enable it to maintain good stability in high-temperature environments, making it suitable for high-temperature processing and use in high-temperature scenarios, such as the manufacture of high-temperature components in the aerospace field.

Density and hardness

Its density is relatively low, at about 4.5g/cm³, which is only about 60% of that of iron. This gives titanium the advantage of being lightweight while possessing a certain degree of strength, making it very competitive in application scenarios where material weight is a concern. In terms of hardness, it has a Mohs hardness of about 6, with good wear resistance and the ability to withstand certain external forces without significant deformation.

Ductility and electrical conductivity

Titanium has a certain degree of ductility and can be processed into different shapes such as thin plates and fine wires through forging, rolling, and other processing methods to meet the diverse needs of industrial production. In terms of electrical conductivity, it is a metallic conductor, but its electrical conductivity is lower than that of some common metals (such as copper and aluminum). It can function normally in application scenarios where electrical conductivity requirements are not high.

Oxidation states and reactivity

The common oxidation states of titanium in compounds are +2, +3, and +4, with +4 being the most common. Titanium is chemically stable at room temperature and rapidly forms a dense oxide film in the air. This oxide film effectively prevents further reactions of titanium with oxygen, water, and other substances, giving it good corrosion resistance. However, under special conditions such as high temperature and strong acids and bases, titanium becomes relatively active and is prone to chemical reactions.

Reaction with acids and bases

At room temperature, titanium has good tolerance to most acids (such as hydrochloric acid and sulfuric acid), with relatively slow reactions. However, it can react with strong corrosive media such as hydrofluoric acid, hot concentrated hydrochloric acid, and aqua regia. In alkaline solutions, titanium is relatively stable at room temperature, but it can be corroded in high-temperature and high-concentration alkaline environments.

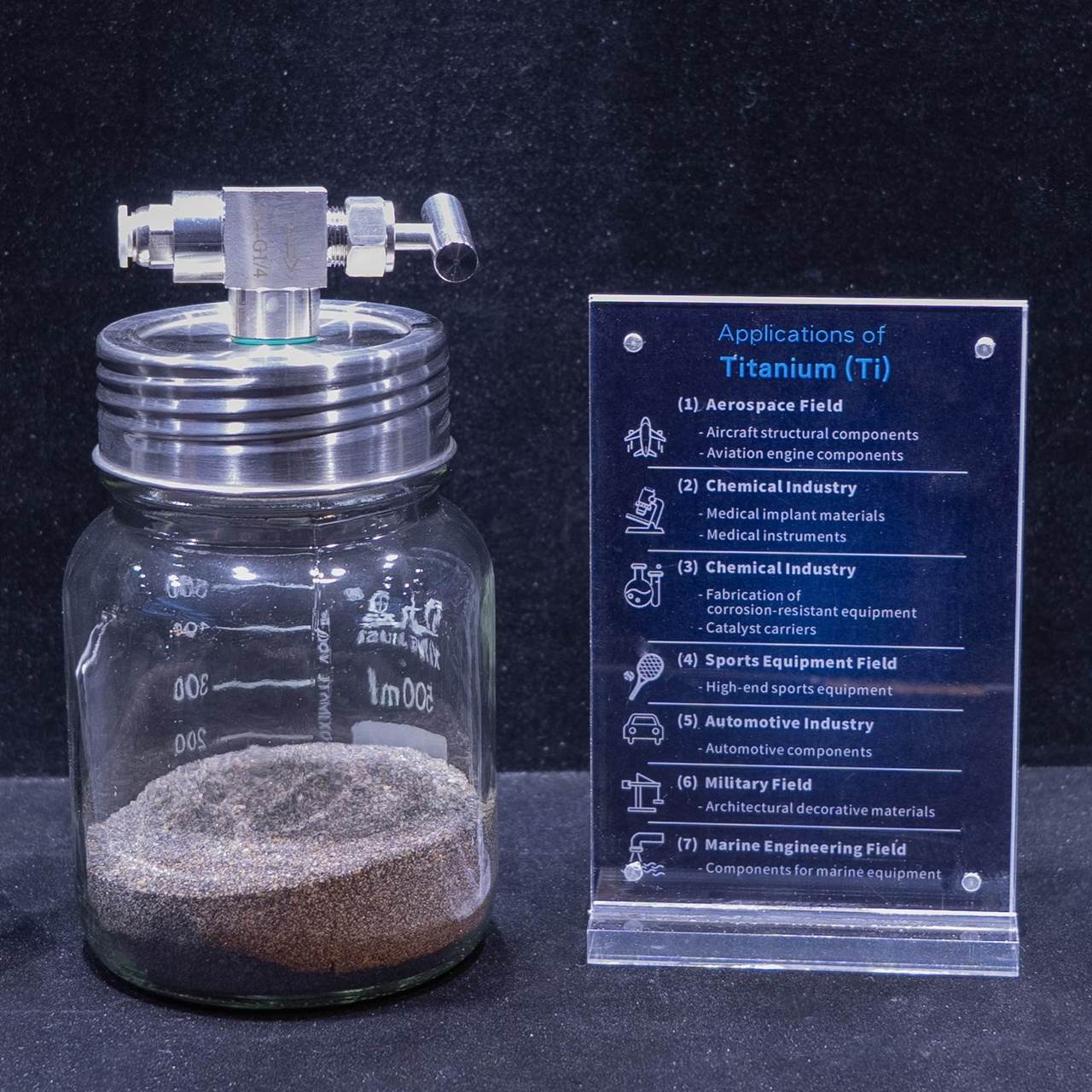

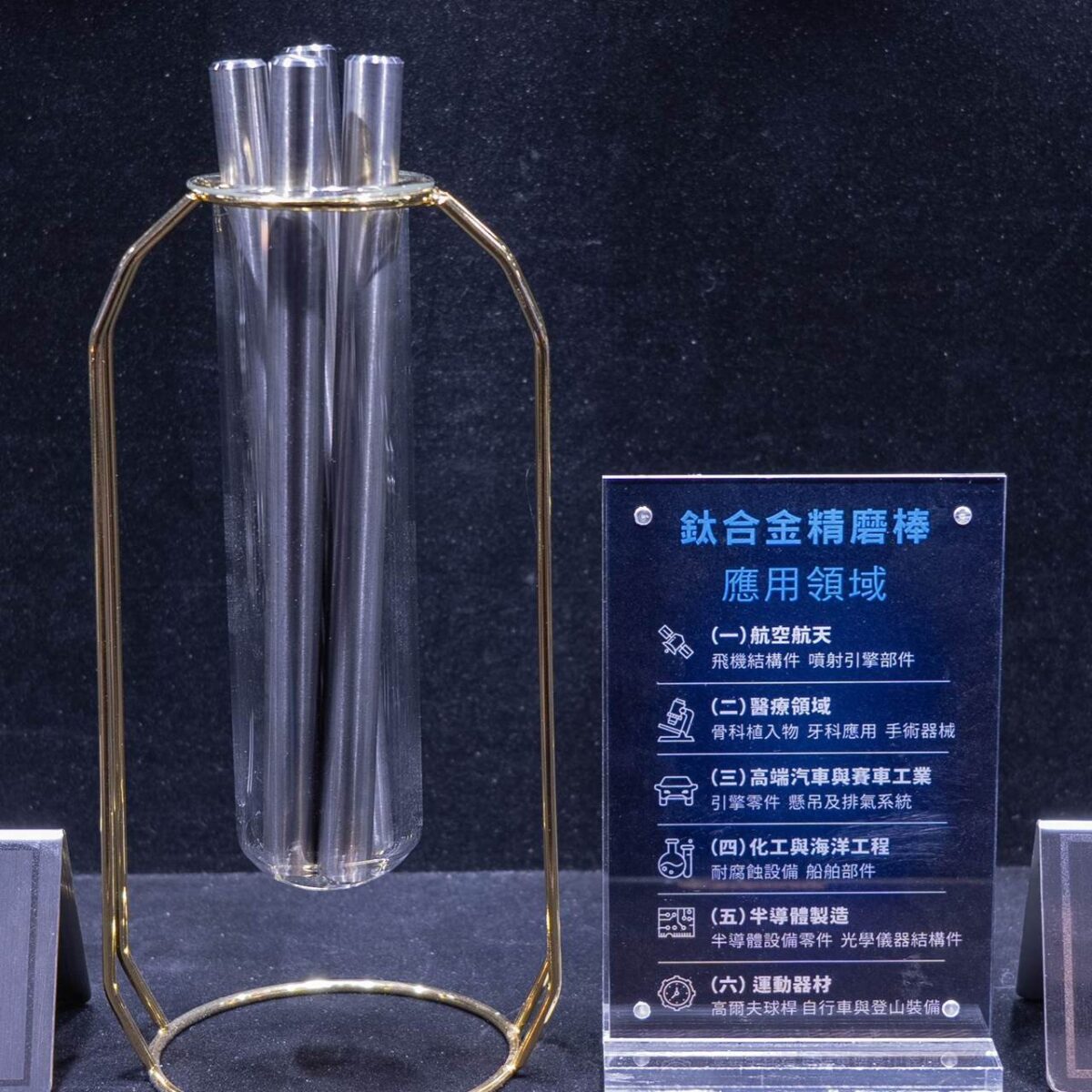

Aerospace Field

Aircraft structural components

Due to its high strength, low density, excellent high-temperature and corrosion resistance, titanium is widely used in the manufacture of key structural components such as the fuselage frame, wings, and landing gear of modern aircraft. For example, the Boeing 787 aircraft extensively uses titanium alloy materials, which helps to reduce the aircraft’s weight, improve fuel efficiency, and ensure reliable operation of the aircraft in complex flight environments and high-stress states.

Aircraft engine components

Aircraft engines need to operate under extreme conditions such as high temperature, high pressure, and high-speed rotation. Titanium alloys can be used to manufacture engine components such as compressor blades, discs, and casings, which can withstand the scouring of high-temperature gas and huge mechanical stress, ensuring the performance and reliability of the engine and extending its service life, promoting the continuous development of the aerospace industry towards high performance.

Medical Field

Medical implant materials

Titanium has very good biocompatibility and generally does not cause immune reactions in the human body. It also has sufficient strength and corrosion resistance, making it an ideal material for manufacturing medical implant devices such as artificial joints, dental implants, and pacemaker casings. These implants can play a stable role in the human body for a long time, helping patients to restore body functions and improve the quality of life.

Medical devices

In some non-implantable medical devices, such as surgical instruments and medical equipment casings, titanium is also used. It’s easy-to-clean and corrosion-resistant properties make medical devices easy to disinfect and use for a long time, meeting the strict requirements of the medical environment.

Chemical Industry

Manufacture of corrosion-resistant equipment

Chemical production often involves harsh environments with various strong acids, strong bases, and corrosive gases. Titanium, with its excellent corrosion resistance, can be used to manufacture chemical equipment such as reactors, heat exchangers, pipelines, and valves. For example, in the chlor-alkali industry, when dealing with highly corrosive chlorine gas and sodium hydroxide solution, titanium equipment can operate stably, effectively reducing equipment maintenance costs and improving the safety and continuity of chemical production.

Catalyst carrier

Some compounds of titanium (such as titanium dioxide) can be used as catalyst carriers, loading active metals and other catalyst components on their surface, which can improve the activity, stability, and dispersibility of the catalyst, playing a role in many chemical reactions such as organic synthesis and petroleum refining, helping to improve the quality and production efficiency of chemical products.

Sports Equipment Field

High-end sports equipment

In the manufacture of high-end sports equipment such as golf clubs, tennis rackets, and bicycle frames, titanium alloys are often chosen. Because it has high strength and can withstand greater sports stress, and is relatively light, it can help athletes better perform at their competitive level. At the same time, it can also improve the durability of the equipment and extend its service life, satisfying the needs of professional athletes and high-end sports enthusiasts. demand.

Automotive Industry

Automotive components

The application of titanium and titanium alloys in the automotive industry is also gradually increasing. For example, using titanium alloys in engine components such as valves, connecting rods, and springs can reduce the weight of the components, improve the performance and fuel economy of the engine, and enhance the wear and fatigue resistance of the components, optimizing the overall performance of the vehicle and meeting the modern automotive industry’s requirements for lightweight and high-performance development.

Construction Field

Construction decoration materials

Titanium and titanium alloy sheets can be used for the exterior decoration of buildings. Due to their unique metallic luster, good corrosion resistance, and shape plasticity, they can create a beautiful and durable appearance. Some iconic modern buildings use titanium as a decorative element to add to the building’s unique charm.

Marine Engineering Field

Marine equipment components

The marine environment has characteristics such as high salinity and strong corrosiveness. Titanium alloy materials are very suitable for manufacturing marine engineering equipment such as structural components of offshore oil platforms, components of seawater desalination devices, and ship propellers. They can resist the erosion of seawater, ensuring the long-term stable operation of equipment in the marine environment and improving the efficiency and safety of marine resource development and utilization.

Related products

Rare Metals

Rare Metals

Rare Metals

Rare Metals