Melting and Boiling Points

Tantalum has an extremely high melting point of 2996°C and a boiling point of around 5425°C. This endows it with superior high-temperature resistance, allowing it to remain solid in many high-temperature environments, making it an outstanding high-temperature resistant material suitable for various stringent high-temperature applications.

Density and Hardness

With a density of 16.65 g/cm³ and a relatively high hardness (approximately 6.5 on the Mohs scale), tantalum possesses good wear resistance and advantages in mechanical processing. It can withstand external forces without easily deforming and can be processed in various forms.

Ductility and Electrical Conductivity

Tantalum has good ductility, enabling it to be processed into different shapes such as extremely thin foils and fine wires to meet diverse industrial processing requirements. Additionally, it is an excellent conductor of electricity with high electrical conductivity, making it an important conductive material commonly used in the electronics field.

Oxidation States and Reactivity

The common oxidation state of tantalum in compounds is +5. However, at room temperature in the atmosphere, a dense oxide film forms on the surface of metallic tantalum, providing it with excellent chemical stability and resistance to erosion by air, water, and most common acids and bases. Under special conditions such as high temperatures and strong oxidation, tantalum can react with oxygen to form corresponding oxides.

Reactions with Acids and Bases

Tantalum has extremely strong corrosion resistance. At room temperature, it is highly resistant to common acids (such as hydrochloric acid, sulfuric acid, nitric acid, etc.) and does not react; it only reacts in specific strong corrosive media such as hydrofluoric acid or a mixture of hydrofluoric acid and nitric acid (similar to aqua regia). In alkaline solutions, tantalum also exhibits high stability and does not undergo significant chemical reactions under conventional alkaline treatment conditions.

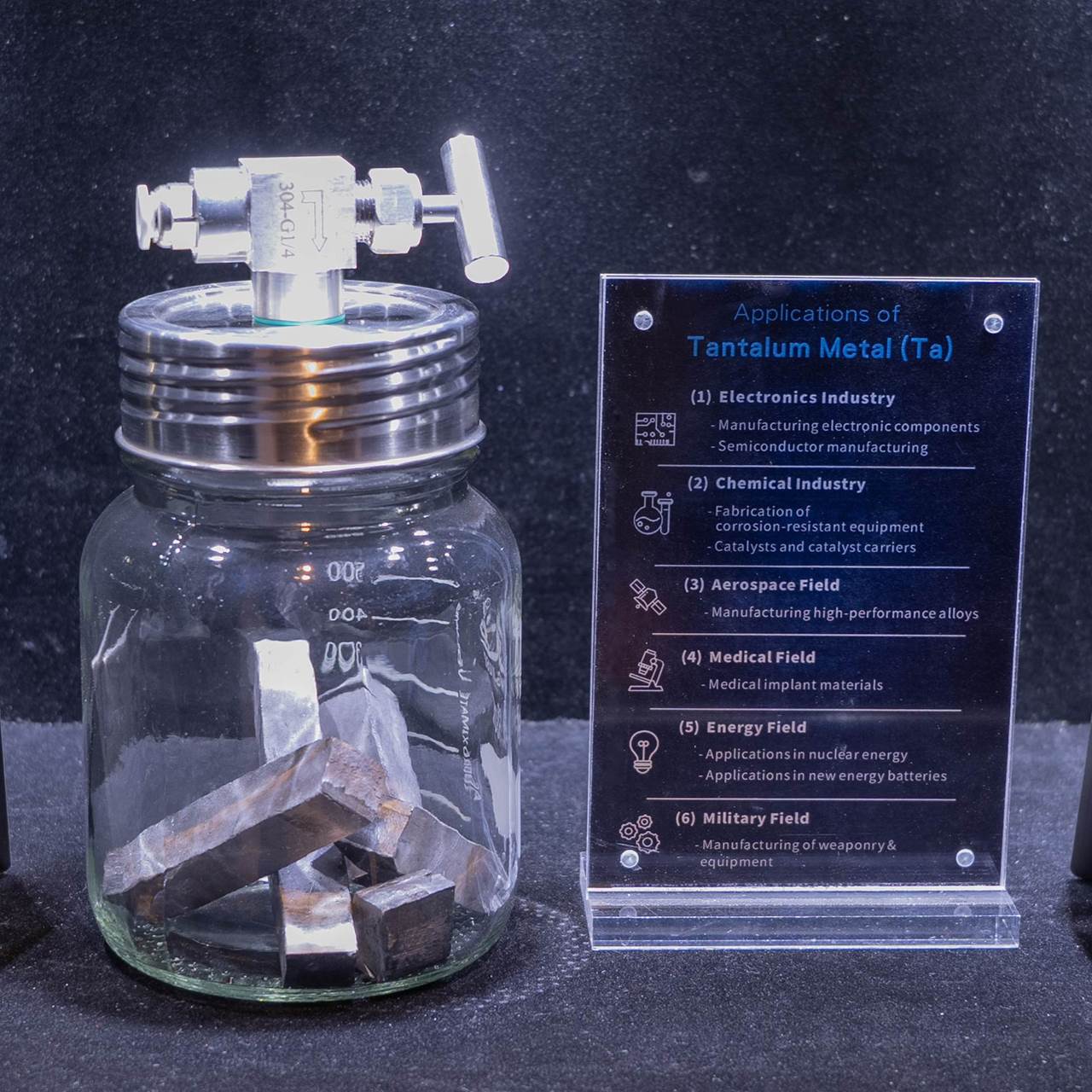

Electronic Industry

Manufacturing Electronic Components

In the electronics field, tantalum is widely used to manufacture various high-performance electronic components. For example, tantalum capacitors are one of its important applications. Tantalum capacitors, with their small size, large capacity, high stability, and low equivalent series resistance, are used as key energy storage components in many electronic devices such as smartphones, computers, and communication base stations, meeting the requirements for miniaturization and high performance of electronic products and ensuring the stable operation of circuits.

Semiconductor Manufacturing

During the manufacturing process of semiconductor chips, tantalum can be used to make components such as electrodes and interconnects. Its good electrical conductivity, compatibility with other materials, high-temperature and chemical stability help improve the performance and reliability of semiconductor chips, promoting the development of electronic devices in a more advanced direction.

Chemical Industry

Manufacturing Corrosion-Resistant Equipment

Chemical production often involves various corrosive media. Due to its extremely strong corrosion resistance, tantalum can be used to manufacture key equipment such as chemical reactors, heat exchangers, and pipes. Especially when dealing with strong acids, strong bases, or high-temperature and highly corrosive media, tantalum equipment can operate stably for a long time, ensuring the smooth progress of chemical production and extending the service life of the equipment. It is widely used in highly corrosive chemical fields such as the chlor-alkali industry and pharmaceutical industry.

Catalysts and Catalyst Carriers

Compounds containing tantalum, made from tantalum as a raw material, can act as catalysts in some chemical reactions, and tantalum itself can also be used as a catalyst carrier to load active components, which can improve the activity, stability, and dispersibility of the catalyst, thereby accelerating the chemical reaction rate and improving the quality of chemical products. It has good application prospects in some processes such as organic synthesis and hydrogenation reactions.

Aerospace Field

Manufacturing High-Performance Alloys

The engines and structural components of aerospace vehicles need to reliably operate in high-temperature, high-pressure, high-stress, and complex space environments. Tantalum, as a key alloying element, is added to high-temperature alloys such as nickel-based and titanium-based alloys. It can significantly improve the high-temperature strength, creep resistance, oxidation resistance, and fatigue resistance of the alloys, ensuring the normal operation of these critical components in harsh environments and safeguarding the flight safety and overall performance of aerospace vehicles.

Medical Field

Medical Implant Materials

Due to its good biocompatibility, moderate mechanical properties, and excellent corrosion resistance, tantalum has become one of the ideal medical implant materials. For example, tantalum can be used to manufacture medical devices such as artificial joints, bone screws, and cranial repair plates, which can stably exist in the human body for a long time without causing significant immune reactions, helping patients to recover and restore body functions.

Energy Field

Applications in Nuclear Energy

In nuclear power generation facilities, tantalum, with its high-temperature resistance, radiation resistance, and good mechanical properties, is used to manufacture key components of nuclear reactors, such as control rods and reflector materials, helping to ensure the safety and stability of nuclear reactors during long-term operation and promoting the safe and efficient use of nuclear energy.

Applications in New Energy Batteries

In the development of some new high-performance batteries, tantalum is also beginning to show its potential. For example, in energy storage battery systems such as all-vanadium redox flow batteries, tantalum can be used to manufacture key components of batteries. With its corrosion resistance and other advantages, it can help improve the performance and service life of batteries, contributing to the development of the new energy industry.

Military Field

Weapon Equipment Manufacturing

In the military, tantalum can be used to manufacture some high-performance weapon equipment components, such as using tantalum-containing alloys in key parts of missiles and artillery, utilizing its high strength, high-temperature resistance, and wear resistance to improve the performance and reliability of weapon equipment and enhance military combat capabilities.

Related products

Rare Metals

Rare Metals

Rare Metals

Rare Metals