Melting and Boiling Points

Niobium-iron has a high melting point, typically around 1500°C to 1700°C, and a high boiling point. These characteristics enable it to maintain good stability in high-temperature environments, making it suitable for applications that require high-temperature processing and usage.

Density and Hardness

Niobium-iron has a relatively high density, generally between 7-8.5 g/cm³, and a significant hardness level compared to pure iron. This endows it with good mechanical properties, allowing it to be processed through forging, rolling, and other methods.

Ductility and Electrical Conductivity

Niobium iron possesses a certain degree of ductility, enabling it to be shaped into different forms. As a metallic conductor, its electrical conductivity differs from that of pure iron due to the presence of niobium, and it can meet the requirements of specific industrial applications for electrical conductivity.

Oxidation States and Reactivity

Niobium commonly exhibits oxidation states of +2, +3, +4, and +5 in compounds. In niobium-iron, niobium interacts with iron and other elements, resulting in good overall chemical stability. Under normal ambient conditions, it does not undergo significant chemical reactions in air. However, under special conditions such as high temperatures and strong oxidation, niobium can be gradually oxidized to form niobium oxides.

Reaction with Acids and Bases

Niobium-iron can react with strong acids. For example, when reacting with diluting hydrochloric acid or diluting sulfuric acid, niobium and iron enter the solution in ionic form, with hydrogen gas being produced. In alkaline solutions, it is relatively stable, but under extreme conditions such as high temperatures and high concentrations of alkali, it may also experience some degree of corrosion or other reactions.

Steel Industry

Enhancing Steel Strength and Toughness

Adding an appropriate amount of niobium-iron to various structural steels, construction steels, and mechanical manufacturing steels allows niobium to combine with carbon and nitrogen in steel to form fine and dispersed carbides and nitrides. These compounds effectively hinder dislocation movement in steel during stress, significantly increasing steel strength. They also refine the grain structure, improving toughness. This enables steel to withstand high loads and impacts without brittle fracture, greatly expanding its application range.

Improving Welding Performance

The addition of niobium-iron can also optimize the welding performance of steel, reducing the probability of defects such as cracks during welding. This is particularly important for large-scale steel structures and pipelines that require welding, helping to ensure welding quality and enhance the safety and stability of the overall structure.

Aerospace Field

Manufacturing High-Performance Alloys

Components such as aerospace engines and structural parts of aircraft often need to operate under extreme conditions, including high temperatures, pressures, stresses, and complex space environments. Niobium-iron can be added as a key alloying element to high-temperature and high-strength alloys such as nickel-based and titanium-based alloys. It enhances the alloys’ high-temperature strength, creep resistance, oxidation resistance, and fatigue resistance, ensuring reliable operation of these critical components and safeguarding the flight safety and overall performance of aerospace vehicles.

Electronics Industry

Manufacturing Electronic Components

In the production of some electronic components, such as capacitors, niobium-iron can be used as a raw material to extract niobium for the manufacture of niobium-based capacitors. Niobium-based capacitors have advantages such as small size, high capacity, and stable performance, meeting the demand for modern electronic devices to become smaller and more powerful. They are widely used in many electronic devices, including smartphones, computers, and communication base stations.

Energy Field

Application in Nuclear Energy

In nuclear power generation facilities, niobium-iron can be used to manufacture alloy materials for key components. With its excellent radiation resistance, high-temperature tolerance, and mechanical properties, it helps ensure the safety and stability of nuclear facilities during long-term operation, improving the efficiency of nuclear energy utilization and promoting the healthy development of the nuclear industry.

Automotive Industry

Enhancing Automotive Component Performance

Adding niobium-iron to the steel used in automotive engine parts, transmissions, chassis, and other components improves the strength, toughness, and wear resistance of these parts. This makes vehicles more reliable and durable during operation and contributes to vehicle lightweighting, reducing energy consumption. It meets the modern automotive industry’s requirements for high performance and environmental protection.

Related products

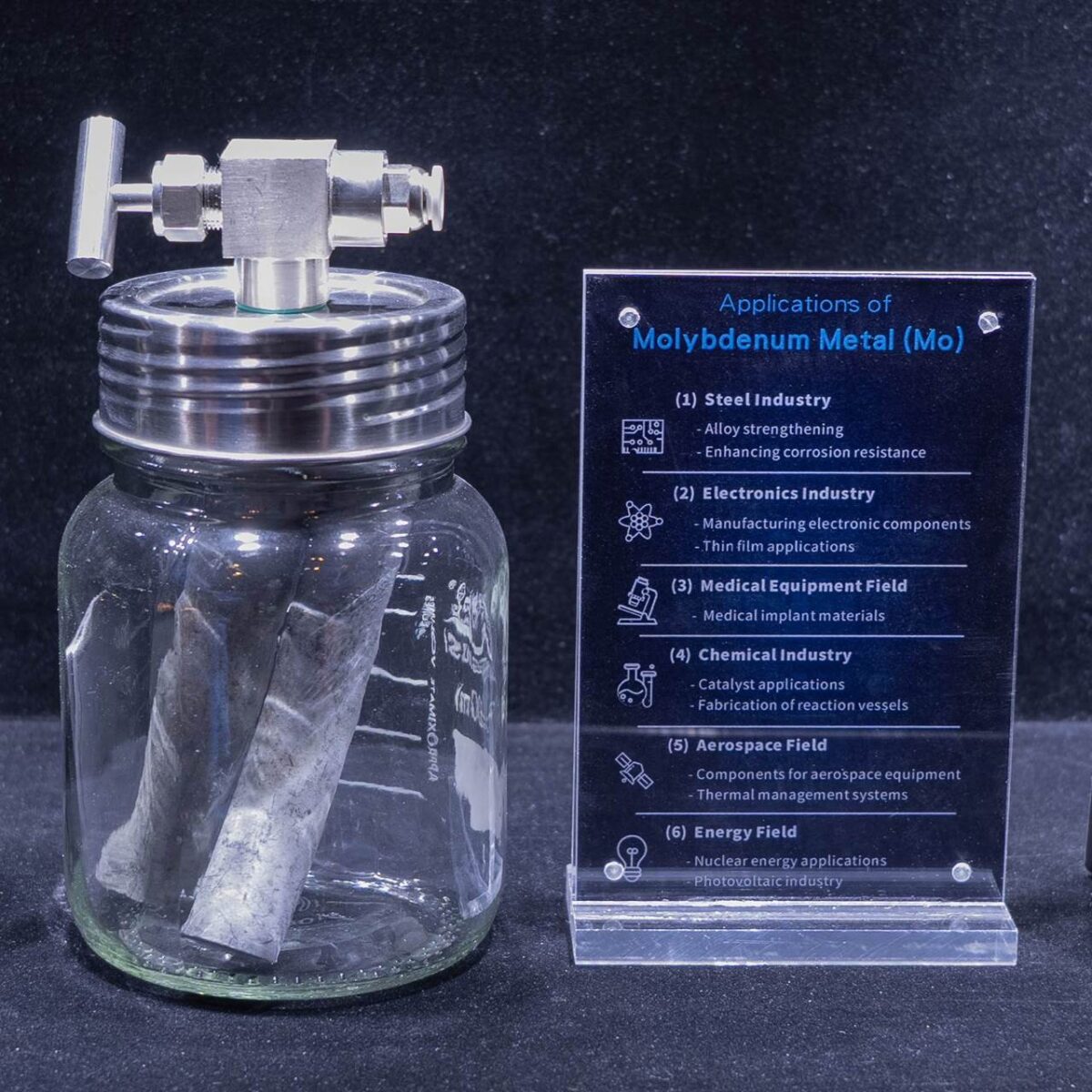

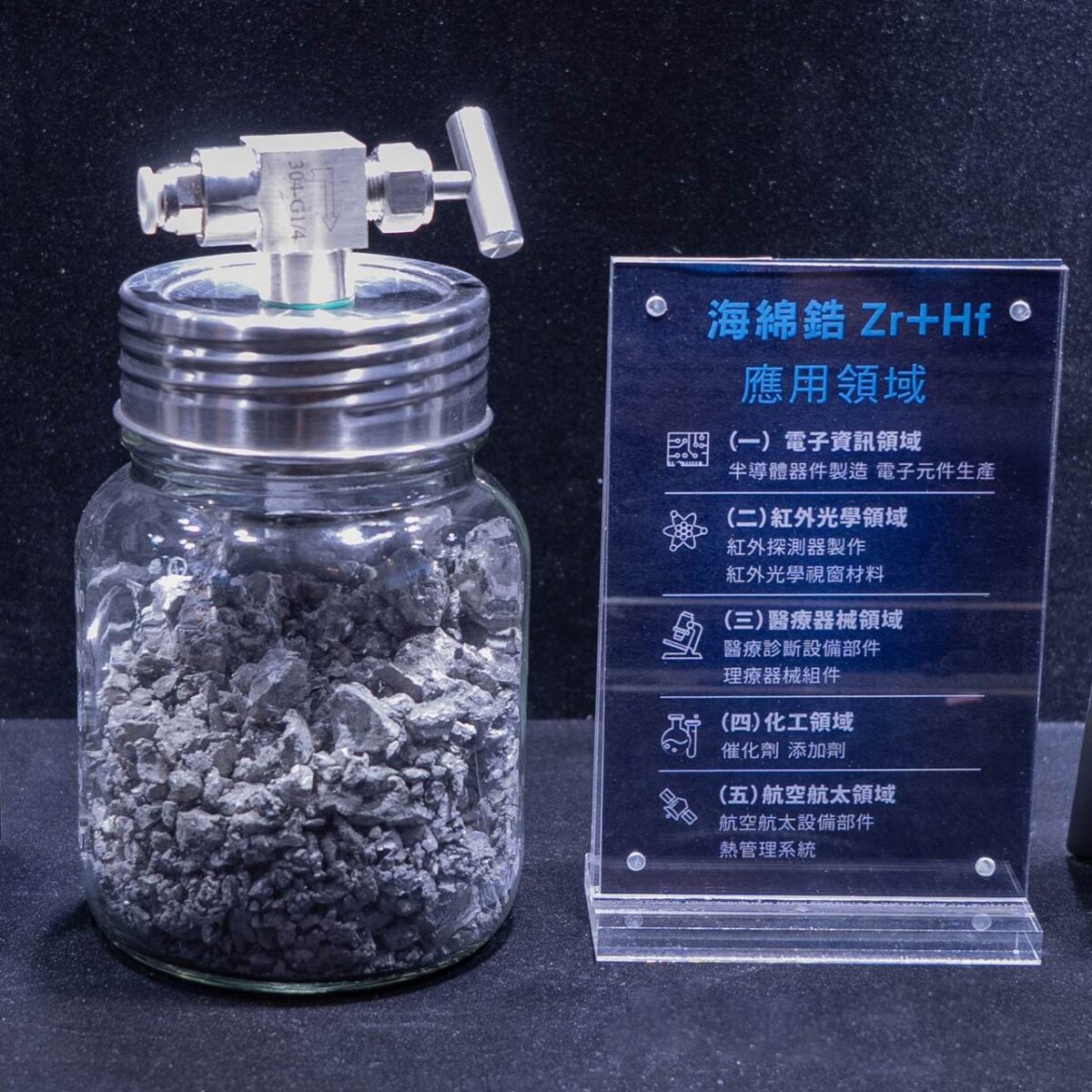

Rare Metals

Rare Metals

Rare Metals

Rare Metals