Melting and Boiling Points

Molybdenum has an extremely high melting point of 2623°C and a boiling point of around 5560°C. This allows it to remain solid in ultra-high-temperature environments, making it ideal for many high-temperature applications due to its excellent high-temperature resistance.

Density and Hardness

With a density of 10.22 g/cm³ and a relatively high hardness (approximately 5.5 on the Mohs scale), molybdenum possesses good wear resistance and advantages in mechanical processing. It can withstand external forces without easily deforming.

Ductility and Electrical Conductivity

Molybdenum has a certain degree of ductility, enabling it to be processed into various shapes such as thin sheets and fine wires to meet diverse industrial processing requirements. Additionally, it is an excellent conductor of electricity with high electrical conductivity, making it valuable in electronic conduction and other applications.

Oxidation States and Reactivity

Molybdenum can exhibit multiple oxidation states in compounds, commonly including +2, +3, +4, +5, and +6. However, at room temperature in the atmosphere, a dense oxide film forms on the surface of metallic molybdenum, providing it with good chemical stability and resistance to erosion by air and water. Under special conditions such as high temperatures and strong oxidation, molybdenum can react with oxygen to form corresponding oxides.

Reactions with Acids and Bases

Molybdenum has strong corrosion resistance. At room temperature, it is relatively resistant to common acids such as hydrochloric acid and dilute sulfuric acid, with slow reaction rates. However, it can react with strong oxidizing acids like nitric acid and aqua regia. In alkaline solutions, molybdenum is relatively stable and does not undergo significant chemical reactions under conventional alkaline treatment conditions.

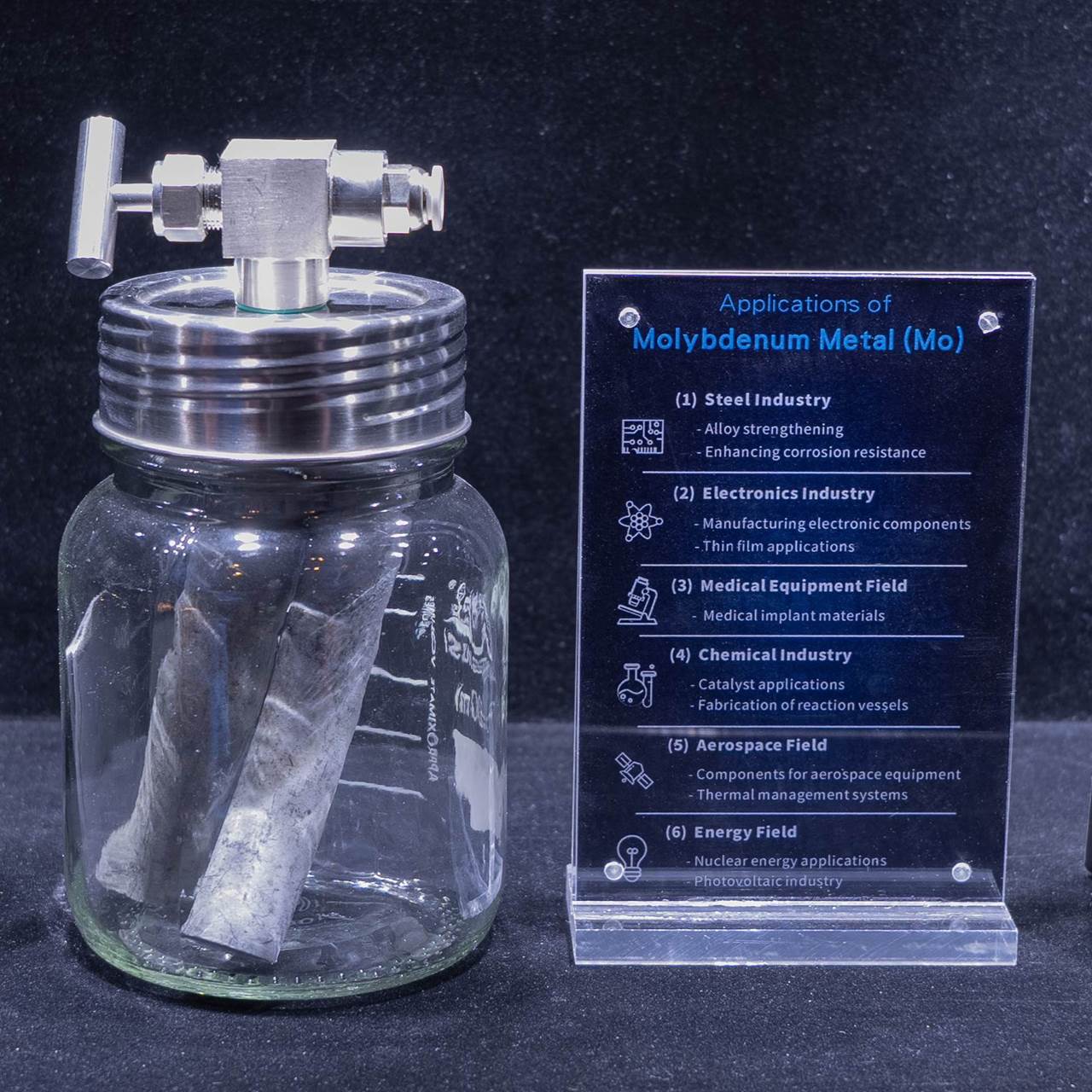

Steel Industry

Alloy Strengthening

In the production of various alloy steels and stainless steels, the addition of molybdenum allows it to form stable carbides, nitrides, and other compounds with carbon and nitrogen in steel. These compounds are dispersed in the steel matrix, effectively hindering dislocation movement, thereby significantly enhancing the strength, hardness, and toughness of steel. This enables steel to withstand greater loads and resist brittle fracture under complex stress conditions, making it widely used in steel reinforcement in fields such as construction and mechanical manufacturing.

Improving Corrosion Resistance

When molybdenum is incorporated into steel, it enhances the steel’s resistance to corrosive environments, especially in harsh corrosive environments containing chloride ions and acidic media. Molybdenum-containing steel can more effectively resist corrosion, extending the service life of steel products. For example, steel used in marine engineering structures and chemical equipment pipelines benefit greatly from the addition of molybdenum in terms of corrosion resistance.

Electronic Industry

Manufacturing Electronic Components

In the semiconductor field, molybdenum is used to manufacture components such as electrodes, lead frames, and interconnect structures in electronic components like transistors and integrated circuits. Its good electrical conductivity, high-temperature stability, and compatibility with other materials help improve the performance and reliability of electronic components, meeting the requirements for miniaturization and high-performance development of electronic devices. It is widely used in numerous electronic products such as smartphones, computers, and communication equipment.

Thin Film Applications

Molybdenum can be made into thin film materials for use in display devices such as liquid crystal displays (LCDs) and organic light-emitting diodes (OLEDs), serving as electrodes and barrier layers. It effectively conducts electricity and prevents mutual diffusion between different materials, ensuring normal operation and good performance of display devices.

Aerospace Field

Manufacturing High-Performance Alloys

Aerospace engines, structural components of aircraft, and other parts need to reliably operate in high-temperature, high-pressure, high-stress, and complex space environments. Molybdenum, as a key alloying element, is added to high-temperature alloys such as nickel-based and titanium-based alloys. It significantly improves the high-temperature strength, creep resistance, oxidation resistance, and fatigue resistance of the alloys, ensuring the normal operation of these critical components in harsh environments and safeguarding the flight safety and overall performance of aerospace vehicles.

Energy Field

Nuclear Energy Applications

In nuclear power generation facilities, molybdenum, with its high-temperature resistance, radiation resistance, and good mechanical properties, is used to manufacture key components of nuclear reactors, such as control rods and reflector materials. This helps ensure the safety and stability of nuclear reactors during long-term operation, promoting the safe and efficient use of nuclear energy.

Photovoltaic Industry

In thin-film solar cells, such as copper indium gallium selenide (CIGS) thin-film solar cells, molybdenum can be used as a back electrode material. Its good electrical conductivity and compatibility with other battery components help improve the photoelectric conversion efficiency of solar cells, promoting the development of the solar photovoltaic industry.

Chemical Industry

Catalyst Applications

Compounds containing molybdenum, made from molybdenum as a raw material, can act as catalysts in many chemical reactions. For example, in hydrogenation desulfurization and hydrogenation denitrification reactions in petroleum refining and chemical synthesis, molybdenum-containing catalysts can effectively reduce the energy activation of reactions, accelerate reaction rates, improve product quality, and help reduce pollutant emissions, meeting environmental requirements.

Manufacturing Reaction Vessels

Molybdenum’s inherent high-temperature and corrosion resistance make it suitable for manufacturing special reaction vessels in chemical production, especially in processes handling high-temperature and strongly corrosive media. Molybdenum vessels can ensure the smooth progress of chemical production and extend the service life of equipment.

Medical Device Field

Medical Implant Materials

Due to its good biocompatibility and certain mechanical properties, molybdenum can be used to manufacture some medical implant materials, such as artificial joints and bone screws, after special treatment. However, its application is currently relatively in the exploration and expansion stage, and it is expected to bring new material choices to the medical device field.

Related products

Rare Metals

Rare Metals

Rare Metals

Rare Metals