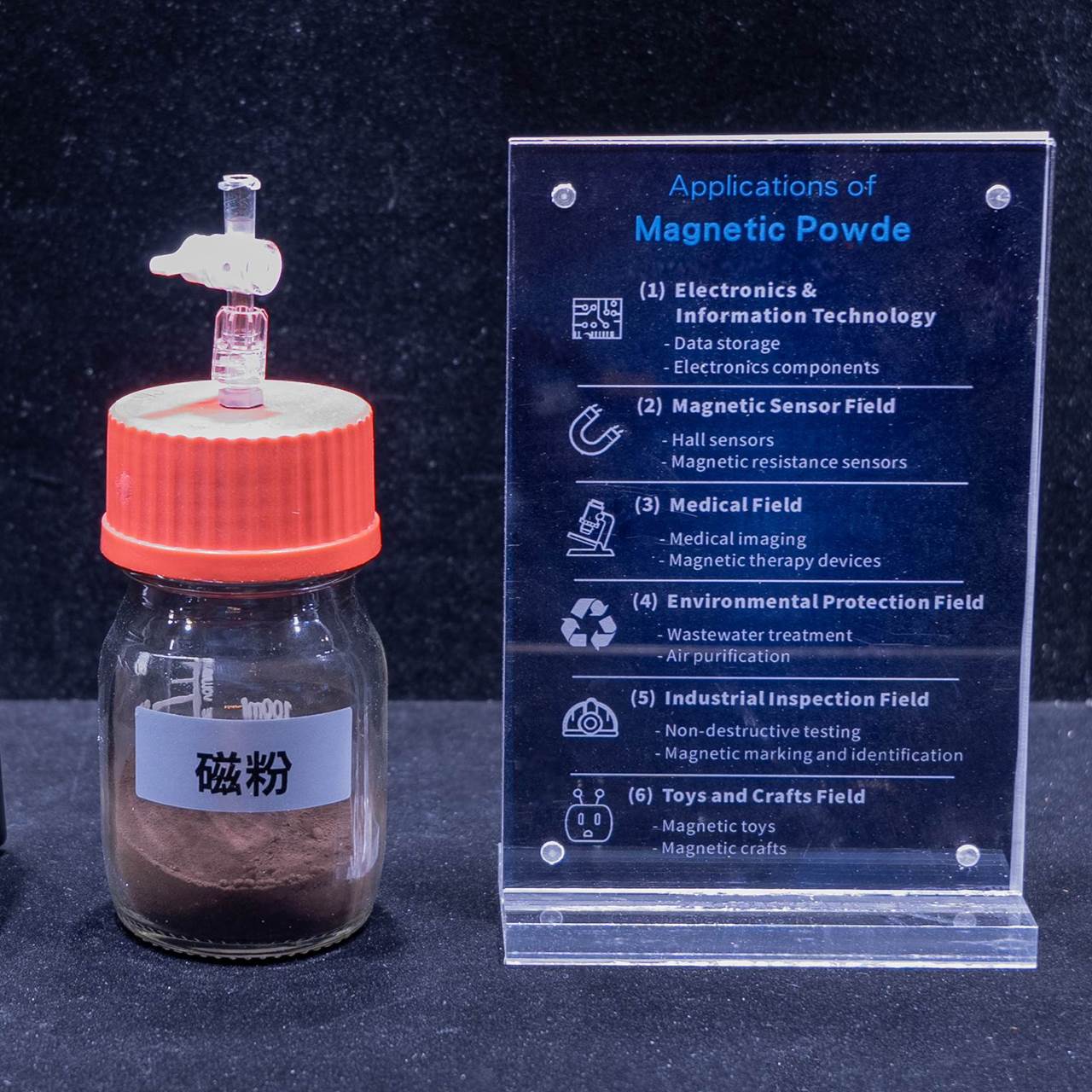

Magnetic Powder

Electronics and Information Technology

Data Storage

Magnetic powder is a key material for manufacturing storage media such as hard disks and magnetic tapes. By incorporating magnetic powder into the magnetic coatings of these media, binary data can be recorded and stored through magnetization, enabling long-term data preservation and rapid read/write operations. This provides a fundamental basis for data storage in computers, servers, and various electronic devices, meeting the demand for high-capacity and high-speed data storage.

Electronic Components

Magnetic powder is used in inductors, transformers, and other electronic components. The magnetic cores made from magnetic powder can effectively enhance the inductance of these components and alter their electromagnetic induction characteristics. This helps regulate current and voltage, enabling the conversion and transmission of electrical energy and ensuring the stable operation of electronic circuits. These components are widely used in electronic devices such as mobile phones, televisions, and power adapters.

Magnetic Sensor Applications

Hall Effect Sensors

In Hall effect sensors, magnetic powder can be used to create sensitive elements. When the external magnetic field changes, the magnetic properties of the powder cause a change in the Hall voltage, allowing for the detection of magnetic field strength and direction. These sensors are widely used in automotive electronic control systems (e.g., speed sensors, throttle position sensors), position detection in industrial automation equipment, and magnetic field measurement, providing important data for precise control and monitoring.

Magneto resistive Sensors

As a key material in magneto resistive sensors, changes in the magnetism of magnetic powder lead to variations in electrical resistance. By detecting these resistance changes, the external magnetic field can be sensed. These sensors are commonly used in electronic compasses and geomagnetic sensors in mobile phones to provide directional information and enable navigation and attitude detection functions.

Medical Applications

Medical Imaging

In magnetic resonance imaging (MRI) devices, magnetic powder is used to produce contrast agents. When injected into the human body, the powder alters the magnetic environment of surrounding tissues, resulting in clearer imaging. This helps doctors more accurately observe the structure and pathology of internal organs and tissues, playing a significant role in the early diagnosis and monitoring of diseases, especially in the examination of neurological and cardiovascular conditions.

Magnetic Therapy Devices

Magnetic powder is used to manufacture various magnetic therapy devices, such as magnetic mattresses, magnetic waist belts, and magnetic patches. The magnetic fields generated by these devices act on specific parts of the human body, stimulating meridians and acupoints to promote blood circulation, relieve pain, and regulate physiological functions. These devices have certain applications in rehabilitation therapy and health care, although their therapeutic effects require further scientific validation.

Environmental Protection

Wastewater Treatment

Magnetic powder can be used as a magnetic adsorbent in wastewater treatment. It can absorb heavy metal ions (such as mercury, cadmium, and lead) and organic pollutants from water. With the help of an external magnetic field, the magnetic powder and the adsorbed pollutants can be easily separated from the water, achieving efficient purification. Compared to traditional wastewater treatment methods, this approach offers advantages such as faster treatment speed and better separation effects, showing promising applications in the treatment of industrial and domestic wastewater.

Air Purification

Magnetic powder is used to produce magnetic air purification materials. Combined with other adsorbents, it can effectively capture dust, harmful gases (such as formaldehyde and benzene), and microorganisms in the air under the influence of a magnetic field, achieving air purification. These materials can be applied in indoor air purifiers and industrial exhaust gas treatment equipment to improve air quality and protect the environment.

Industrial Inspection

Non-Destructive Testing

In non-destructive testing techniques, such as magnetic particle inspection, a testing liquid containing magnetic powder is applied to the surface of a metal workpiece. When the workpiece is magnetized, if there are defects such as cracks or pores inside, the magnetic powder will gather at these defect sites, forming magnetic traces. By observing these traces, defects in the workpiece can be detected. This method is widely used in quality inspection of metal components in industries such as aerospace, mechanical manufacturing, and petrochemicals, ensuring product quality and safety.

Magnetic Marking and Identification

Magnetic powder is used to mark industrial products and components. With specialized magnetic detection equipment, products can be easily identified and tracked, enabling quality control and logistics management in the production process. This improves the efficiency and accuracy of industrial production and management.

Toys and Craft Applications

Magnetic Toys

Magnetic powder is an essential material for making various magnetic toys, such as magnetic building blocks and magnetic puzzles. The magnetic properties of the powder allow toy parts to attract and combine with each other, stimulating children’s hands-on skills, spatial imagination, and creativity. These toys are popular among children and have a wide range of applications in the toy market.

Magnetic Crafts

Magnetic powder is also used in the production of creative and decorative magnetic crafts, such as magnetic refrigerator magnets and magnetic bookmarks. These crafts not only add fun and functionality to the items but also allow them to be conveniently attached to surfaces with magnets, meeting people’s practical and aesthetic needs.