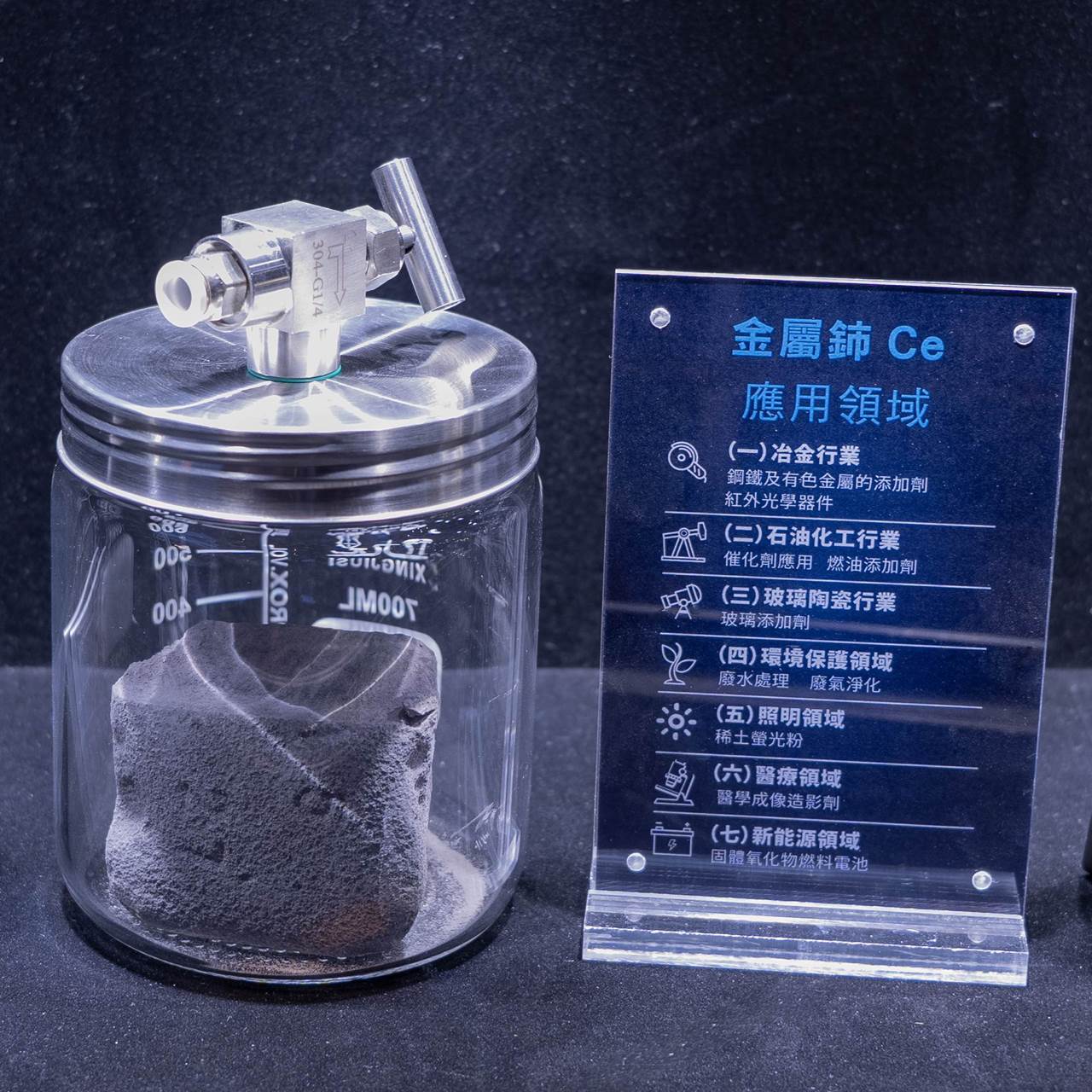

Cerium

Melting and Boiling Points

Cerium has a melting point of 798°C and a boiling point of 3443°C. Its relatively low melting point allows it to play a unique role in medium and low-temperature processing and applications, while its high boiling point ensures a certain degree of stability in high-temperature environments.

Density and Hardness

Cerium has a density of approximately 6.77 g/cm³ and low hardness, with a Mohs hardness of about 2.5. Its relatively soft texture makes it easy to process into different forms, such as powders and thin sheets, in specific manufacturing processes.

Ductility and Electrical Conductivity

Cerium exhibits a certain degree of ductility, allowing it to be deformed through processing. As a metallic conductor, its electrical conductivity is weaker than that of common metals like copper and aluminum, but it still meets the requirements of some applications where high electrical conductivity is not essential.

Oxidation States and Reactivity

Cerium commonly exhibits oxidation states of +3 and +4 in compounds. It is chemically reactive and can react with oxygen in the air at room temperature to form a surface oxide layer, which to some extent slows down further oxidation. Under heated conditions, cerium can react significantly with oxygen, water, and many common acids and bases.

Reaction with Acids and Bases

Cerium can react with common acids such as diluting hydrochloric acid and dilute sulfuric acid to form cerium salts (e.g., cerium chloride, cerium sulfate) and release hydrogen gas. It also reacts with alkaline solutions, such as sodium hydroxide, demonstrating its characteristic reactivity as a reactive metal.

Metallurgical Industry

Additive for Steel and Nonferrous Metals

In steel production, the addition of an appropriate amount of cerium serves as a deoxidizer and desulfurizer, purifying the molten steel and improving the quality of steel. Cerium also refines the grain structure, enhancing the toughness, wear resistance, and corrosion resistance of steel, making it more effective in construction and mechanical manufacturing. In nonferrous metals like aluminum and magnesium, cerium improves casting properties, mechanical properties, and oxidation resistance. For example, in aluminum alloys, cerium increases strength and heat resistance, expanding their application range.

Rare Earth Permanent Magnet Materials

Cerium is an essential raw material for manufacturing rare earth permanent magnets. Combined with other rare earth elements and metals, and processed through special techniques, these magnets are used in motors, generators, and electronic devices, providing stable and strong magnetic fields to enhance the efficiency and performance of these devices.

Petrochemical Industry

Catalyst Applications

Compounds of cerium are commonly used as catalysts or catalyst promoters in petroleum refining and chemical production. For example, in petroleum cracking, cerium-containing catalysts improve the efficiency of the cracking reaction, increasing the yield of light oils such as gasoline. In organic synthesis reactions (e.g., oxidation and hydrogenation), cerium compounds accelerate reactions and improve product quality, contributing to more efficient and high-quality chemical production.

Fuel Additives

Cerium compounds can be formulated into fuel additives for gasoline and diesel, enhancing combustion and reducing carbon deposits. This leads to more complete fuel combustion, lowering pollutant emissions in exhaust gases and benefiting the environment. It also improves engine performance and fuel economy to some extent.

Glass and Ceramic Industry

Glass Additives

In glass manufacturing, cerium serves multiple purposes. For optical glass, cerium absorbs ultraviolet light, improving transparency and optical properties, and is commonly used in products like eyeglass lenses and camera lenses. In architectural glass, cerium enhances radiation resistance, making it suitable for applications such as observation windows in nuclear power plants. In ceramics, cerium improves color, hardness, and high-temperature resistance, enhancing the quality of ceramic products.

Environmental Protection Field

Wastewater Treatment

Some cerium compounds can be used in wastewater treatment to remove heavy metal ions (e.g., mercury, lead) and certain organic pollutants through adsorption and precipitation, purifying water quality and meeting environmental protection requirements.

Exhaust Gas Purification

In the treatment of industrial exhaust gases (e.g., sulfur dioxide, nitrogen oxides), cerium-containing catalysts promote the conversion of harmful components into harmless substances, reducing atmospheric pollutant emissions and minimizing environmental pollution.

Lighting Field

Rare Earth Phosphors

Cerium is a key component in the production of rare earth phosphors. Combined with other elements, it can produce phosphors of various colors and excellent performance, used in lighting products such as fluorescent lamps and LED lights. These phosphors improve light emission efficiency, color rendering, and service life, providing better lighting environments.

Medical Field

Medical Imaging Contrast Agents

Certain compounds of cerium have potential applications in medical imaging. After special processing, they may serve as contrast agents to help doctors more clearly observe internal tissues and pathological conditions in the human body. However, most of these applications are still in the research and exploration stages and have not yet been widely used in clinical practice.

New Energy Field

Solid Oxide Fuel Cells

In the development of solid oxide fuel cells, cerium compounds can be part of the electrolyte or electrode materials. Utilizing their ionic conductivity and chemical stability, they contribute to enhancing fuel cell performance and advancing new energy technologies, offering new pathways for solving energy issues.