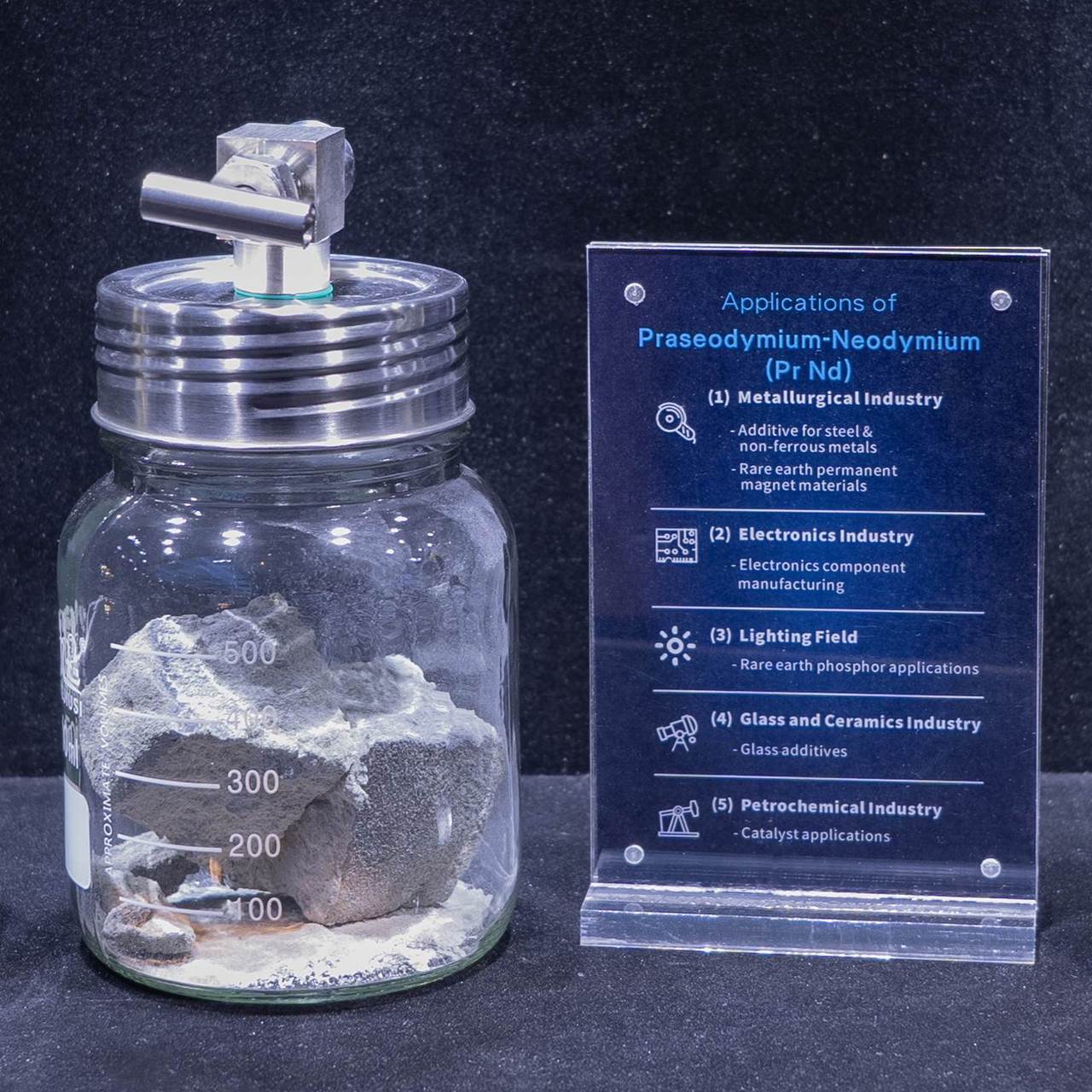

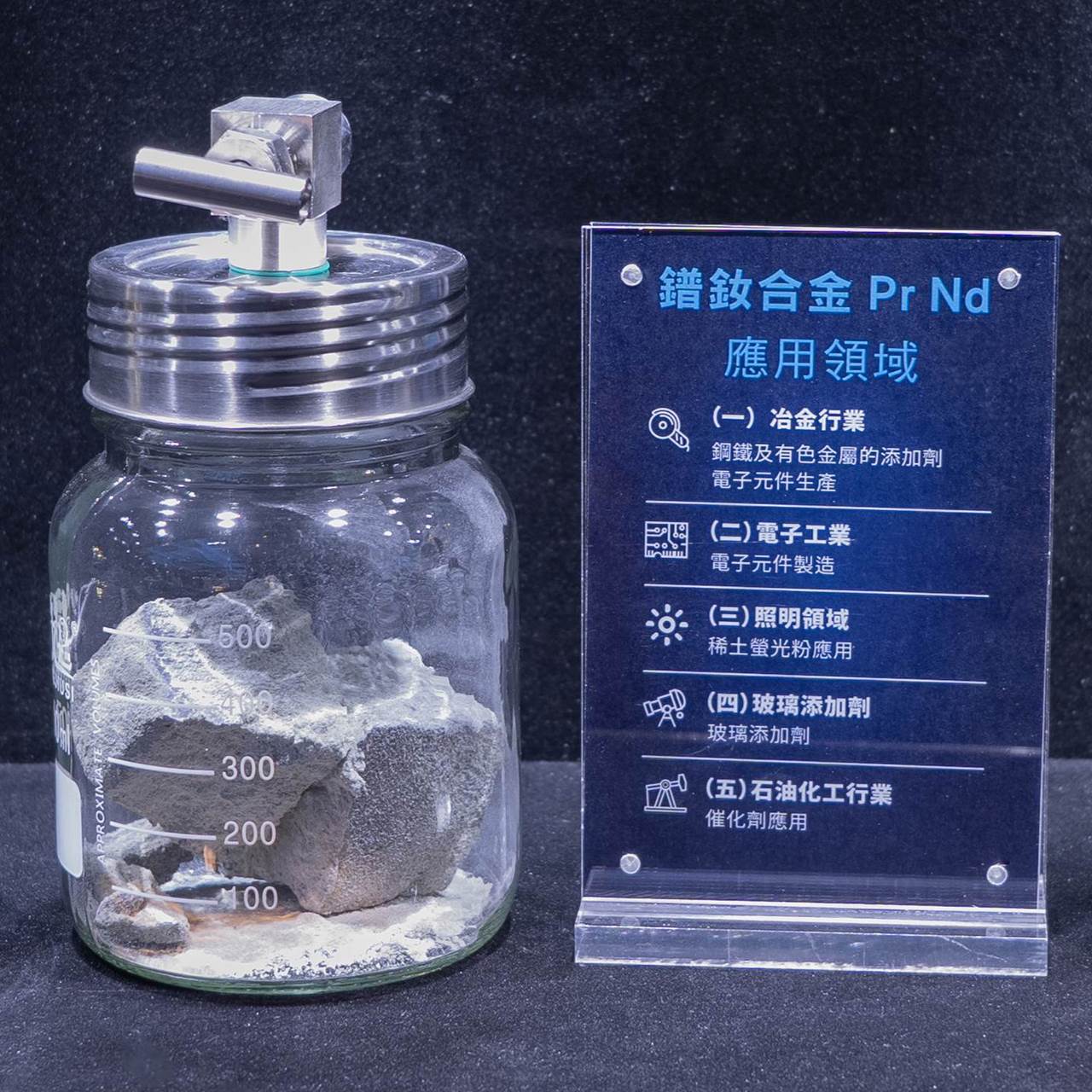

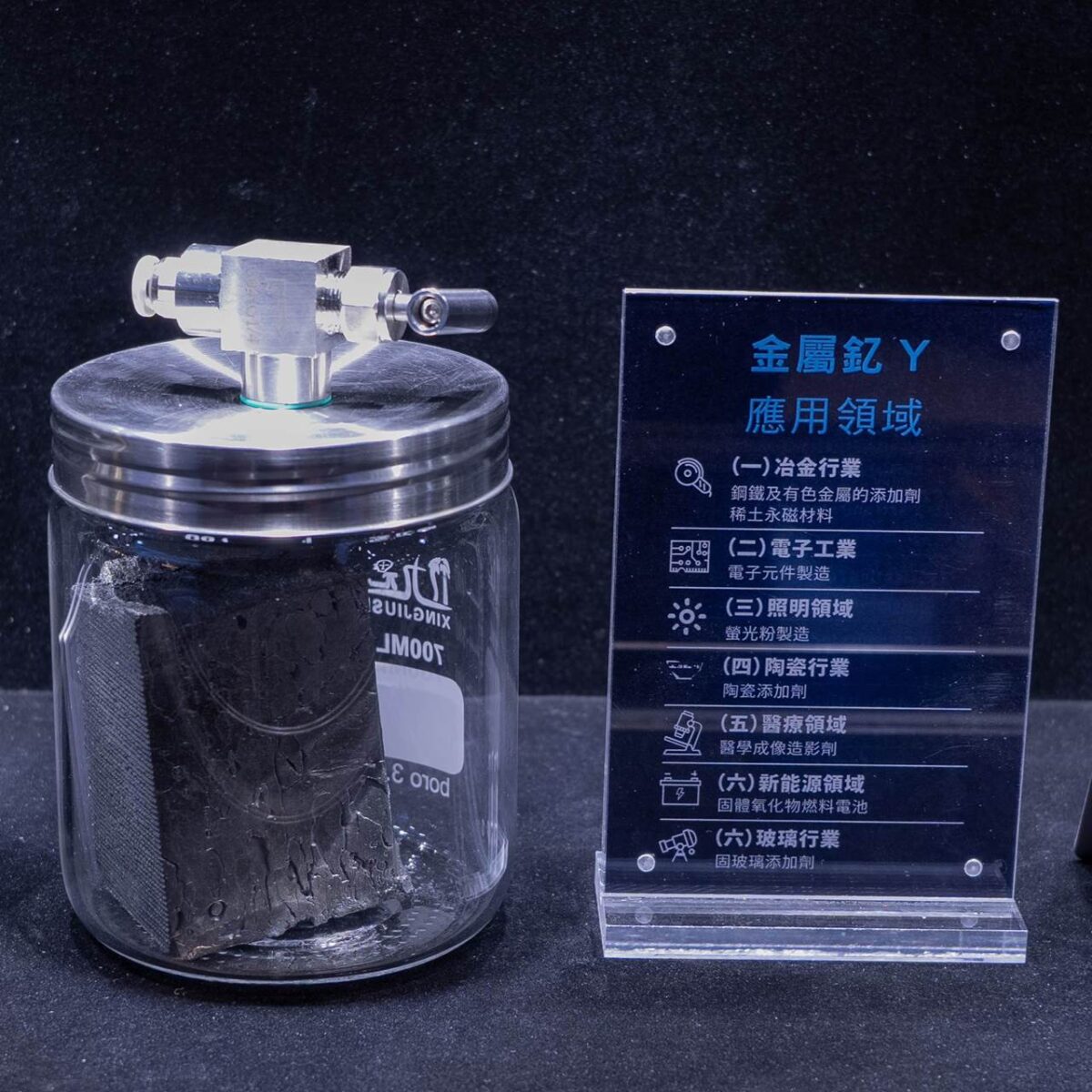

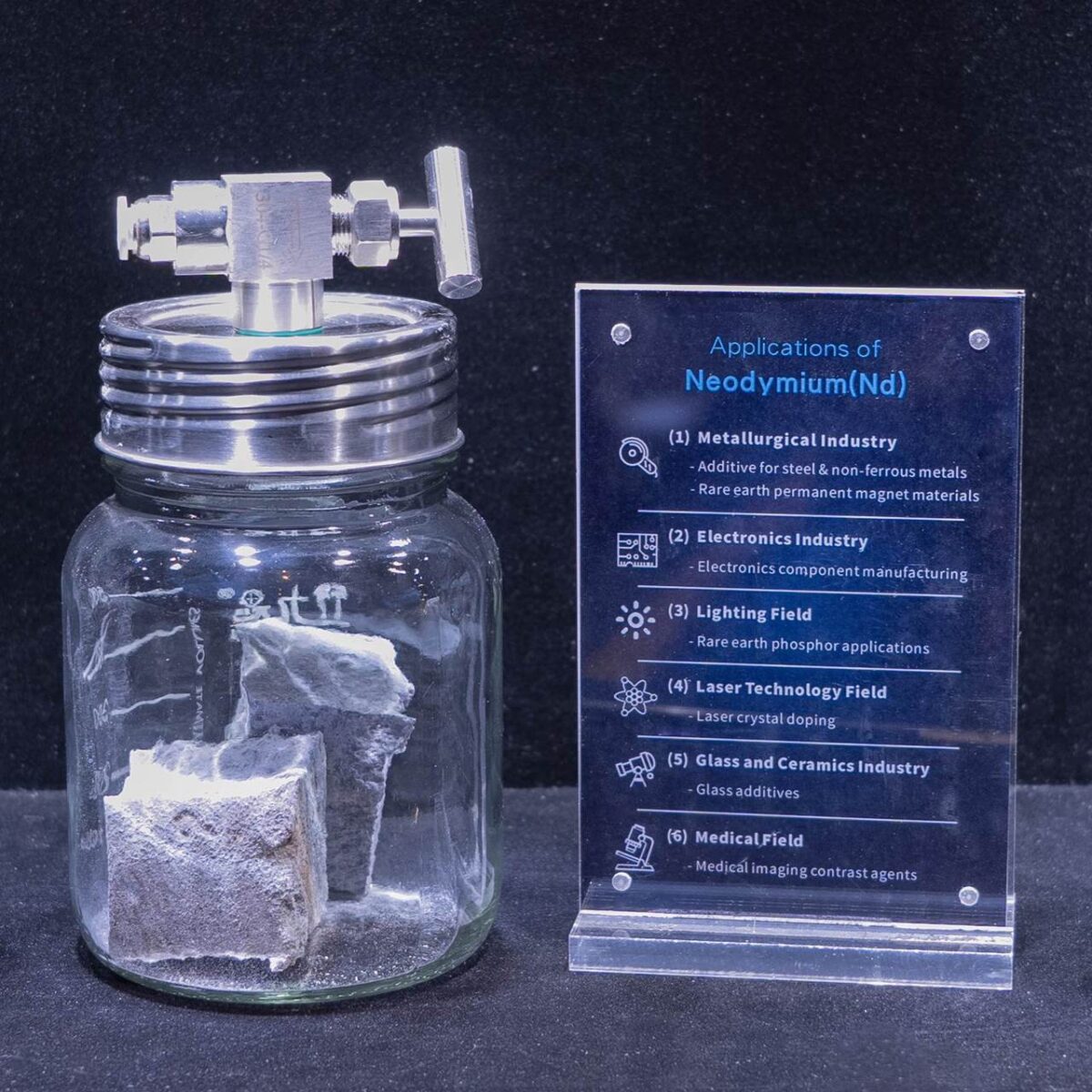

Praseodymium-Neodymium Alloy

Melting and Boiling Points

The melting and boiling points of praseodymium-neodymium mixtures lie between those of pure praseodymium and neodymium. Typically, the melting point is around 900°C – 1000°C, while the boiling point ranges from 3000°C to 3500°C. The high boiling point provides good thermal stability, making it suitable for high-temperature processing and applications in high-temperature environments. The melting point range also facilitates processing under specific thermal conditions.

Density and Hardness

The density of praseodymium-neodymium mixtures is approximately 6.5 – 7.5 g/cm³, with a moderate hardness that ranges from 4 to 6 on the Mohs scale. These properties provide sufficient mechanical strength to withstand external forces during processing and allow the material to be shaped through conventional methods such as forging and rolling to meet specific production needs.

Ductility and Electrical Conductivity

Praseodymium-neodymium has a certain degree of ductility, enabling it to be processed into thin sheets and fine wires for various industrial applications. As metallic conductors, their electrical conductivity is slightly lower than that of common metals such as copper and aluminum but is still sufficient for applications where high electrical conductivity is not a primary requirement.

Oxidation States and Reactivity

The common oxidation states of praseodymium in compounds are +3 and +4, while neodymium typically exhibits a +3 oxidation state. In praseodymium-neodymium mixtures, the overall chemical nature is quite reactive. At room temperature, they can react with oxygen in the air to form an oxide layer on the surface, which helps to slow down further oxidation. More pronounced chemical reactions occur under conditions such as heating or contact with acids or bases, following similar chemical patterns as individual praseodymium and neodymium elements.

Reactions with Acids and Bases

Praseodymium-neodymium can react with common acids such as diluting hydrochloric acid and dilute sulfuric acid to form corresponding salts (e.g., praseodymium chloride, neodymium chloride, praseodymium sulfate, neodymium sulfate) while releasing hydrogen gas. They also react with alkaline solutions, demonstrating the characteristics of reactive metals in acid-base reactions and following the general rules of such reactions.

Metallurgical Industry

Additive in Steel and Non-Ferrous Metals

In steel production, the addition of praseodymium-neodymium serves as a deoxidizer and desulfurizer, effectively purifying the steel melt and improving steel quality. Moreover, praseodymium-neodymium can refine steel grains, enhance the toughness, wear resistance, and corrosion resistance of steel. This makes steel more suitable for applications in construction and mechanical manufacturing. In non-ferrous metals such as aluminum and magnesium, the addition of praseodymium-neodymium improves casting properties, mechanical performance, and oxidation resistance. For example, in aluminum alloys, praseodymium-neodymium can increase strength and heat resistance, expanding their application range.

Rare Earth Permanent Magnets

Praseodymium-neodymium is a key raw material for manufacturing high-performance rare earth permanent magnets, especially in the production of neodymium-iron-boron (NdFeB) permanent magnets. Combined with iron and boron, they are processed into permanent magnets through specific techniques. These magnets offer extremely high energy products, strong coercivity, and good cost-effectiveness. They are widely used in motors, generators, electric vehicles, wind power equipment, consumer electronics (such as mobile phones, computer hard disk drives), and medical devices. They provide strong and stable magnetic fields, significantly enhancing the efficiency and performance of these devices.

Electronics Industry

Electronic Component Manufacturing

In the production of electronic components such as electronic transformers and inductors, praseodymium-neodymium can be processed to extract praseodymium and neodymium for the manufacture of components containing these elements. These components exhibit unique electromagnetic properties, such as high magnetic permeability and low magnetic loss, meeting the demands of modern electronic devices for miniaturization and high performance. They are widely used in various electronic devices, including smartphones, computers, and communication base stations.

Lighting Field

Rare Earth Phosphors

Praseodymium-neodymium is an important component in the production of rare earth phosphors. Combined with other elements, they can produce phosphors with different colors and excellent performance. These phosphors are used in lighting products such as fluorescent lamps and LED lights, improving luminous efficiency, color rendering, and lifespan, creating a better lighting environment for people.

Glass and Ceramic Industry

Glass Additives

In glass manufacturing, the addition of praseodymium-neodymium brings multiple benefits. For optical glass, praseodymium-neodymium can absorb specific wavelengths of light, altering the optical properties of the glass. This is useful in the production of optical elements such as color filters and polarizing mirrors. In architectural glass, praseodymium-neodymium enhances radiation resistance, making it suitable for special environments like observation windows in nuclear power plants. In ceramic production, praseodymium-neodymium improves the color, hardness, and high-temperature resistance of ceramics, enhancing the quality of ceramic products and is often used in the manufacture of high-end ceramics.

Petrochemical Industry

Catalyst Applications

Compounds of praseodymium-neodymium are commonly used as catalysts in petroleum refining and chemical production. For example, in petroleum cracking processes, praseodymium-neodymium-containing catalysts can improve cracking efficiency, increasing the yield of light oils such as gasoline. In organic synthesis reactions (such as oxidation and hydrogenation reactions), praseodymium-neodymium compounds can accelerate reaction rates and improve product quality, contributing to more efficient and higher-quality production in the chemical industry.