Dysprosium-Iron Alloy

Melting and Boiling Points

Dysprosium-iron alloy has a relatively high melting point, typically between 1300°C and 1500°C, and a high boiling point. These characteristics provide good thermal stability, making it suitable for high-temperature processing and applications in environments with elevated temperatures, such as the preparation of magnetic materials under high-temperature conditions.

Density and Hardness

The density of dysprosium-iron alloy is higher than that of pure iron, generally ranging from 7.5 to 8.5 g/cm³. It also has a higher hardness than pure iron, which endows it with better mechanical properties. This makes it easier to process through forging, rolling, and other methods to meet specific shape requirements for production.

Ductility and Electrical Conductivity

Dysprosium-iron alloy has a certain degree of ductility, although it is slightly weaker than some common metals. As a metallic conductor, its electrical conductivity differs from that of pure iron due to the presence of dysprosium. It can meet basic electrical conductivity requirements in specific industrial applications, such as those involving electromagnetic components.

Oxidation States and Reactivity

Dysprosium commonly exhibits an oxidation state of +3 in compounds. In the alloy, dysprosium interacts with iron and other impurities, resulting in good overall chemical stability. At room temperature, dysprosium-iron alloys do not readily undergo chemical reactions in normal environments. However, under special conditions such as high temperatures and strong oxidation, the dysprosium element can gradually oxidize, forming corresponding dysprosium oxides.

Reactions with Acids and Bases

Dysprosium-iron alloy can react with strong acids. For example, when it reacts with diluted hydrochloric acid or diluted sulfuric acid, dysprosium and iron enter the solution in ionic form, accompanied by the release of hydrogen gas. In alkaline solutions, the alloy is relatively stable, but under extreme conditions such as high temperatures and high-concentration alkali, it may experience some degree of corrosion or reaction.

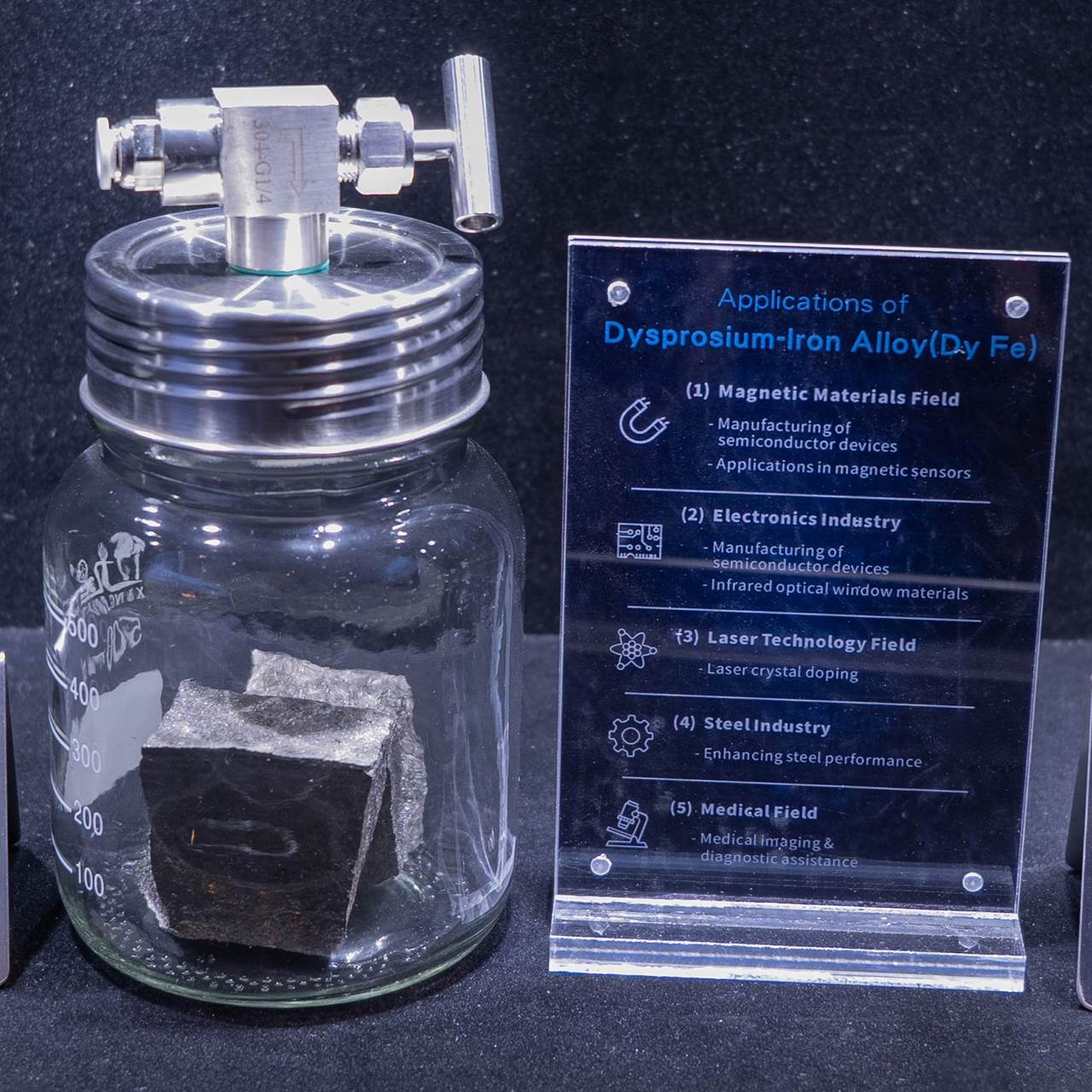

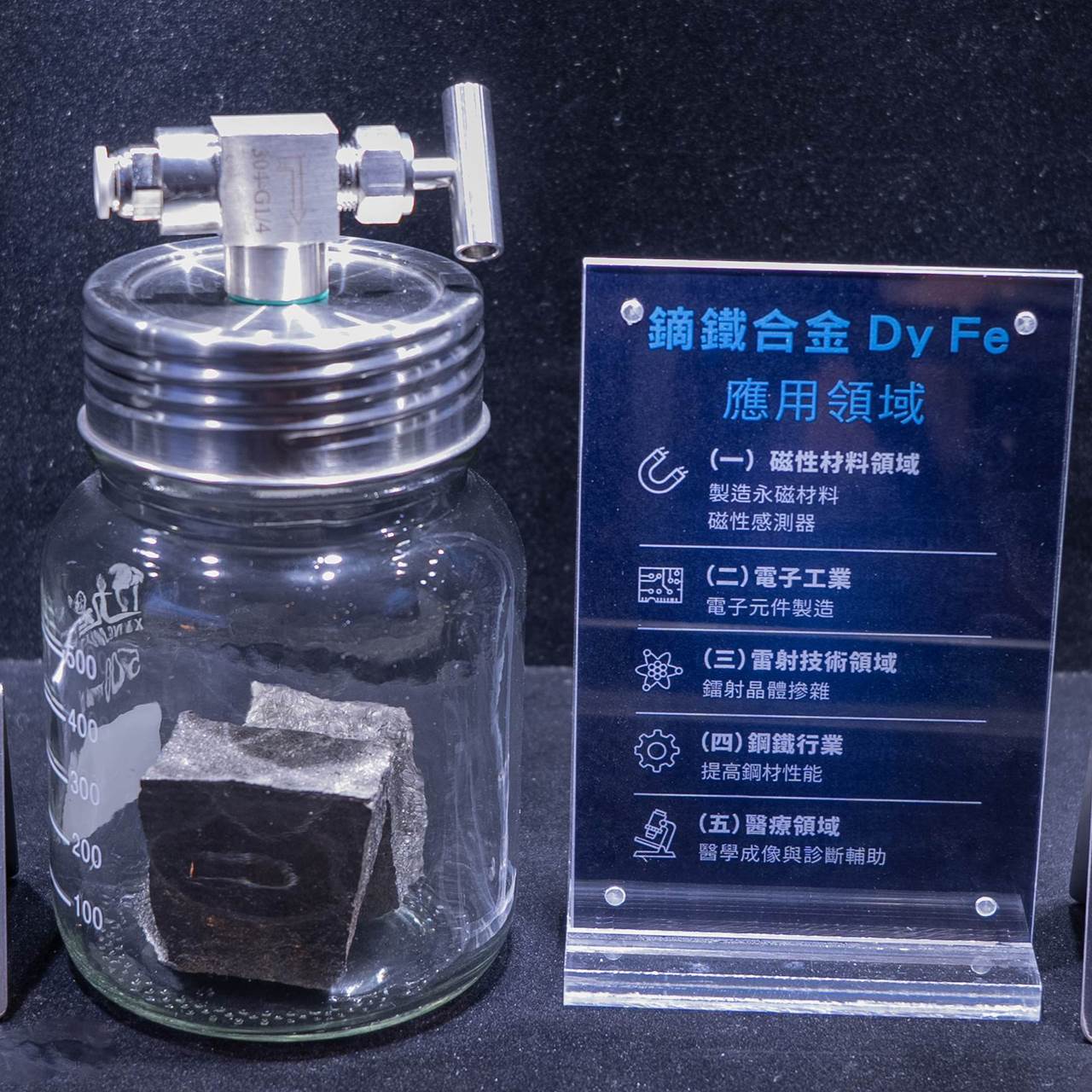

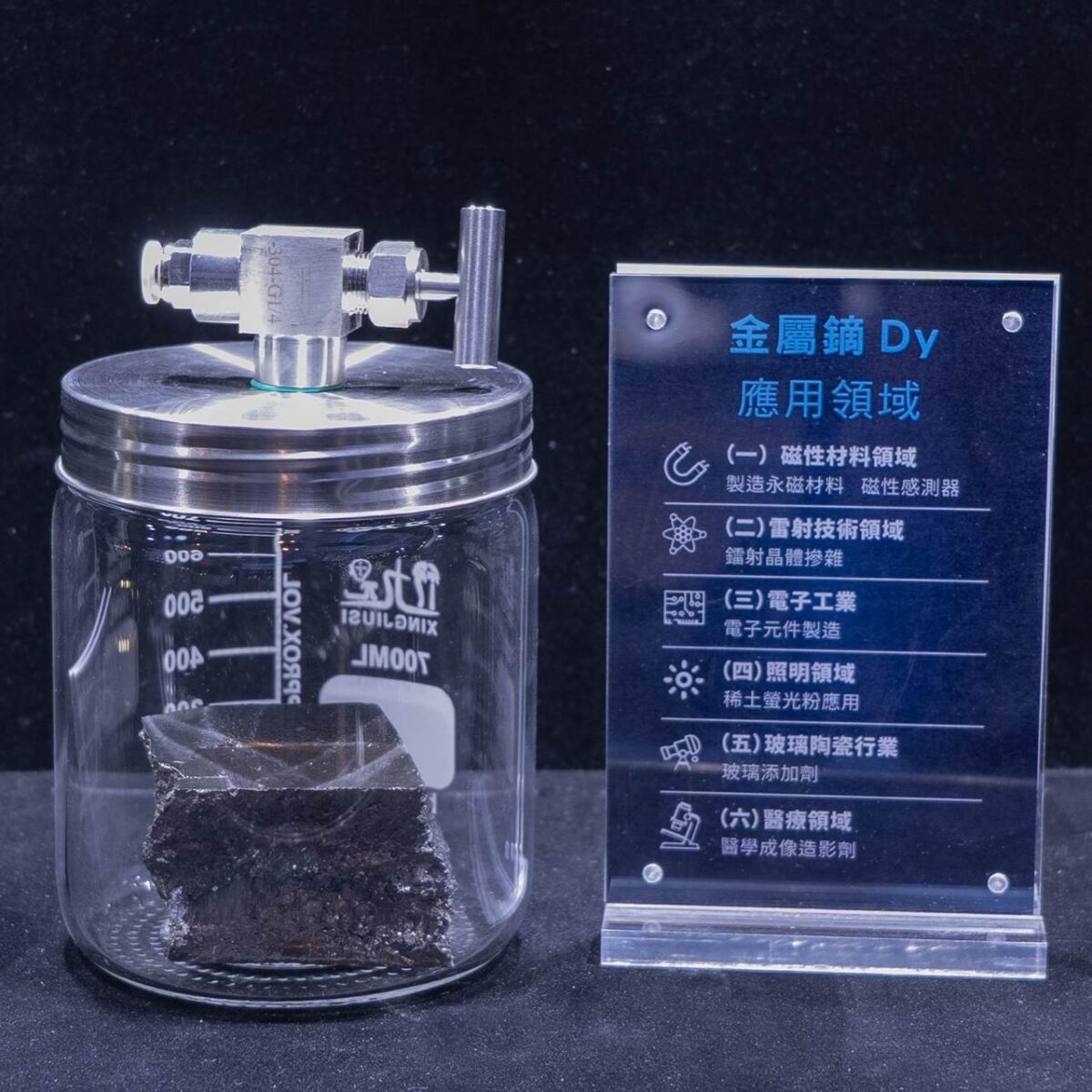

Magnetic Materials

Permanent Magnet Manufacturing

Dysprosium, a rare earth element with strong magnetic properties, is used in the production of high-performance permanent magnets after specific processing and magnetization of the alloy. These magnets are crucial in devices with extremely high requirements for magnetic field strength and stability, such as drive motors for electric vehicles, generators for wind turbines, high-precision industrial motors, and speakers in high-end audio equipment. They provide strong and stable magnetic fields, ensuring efficient operation and excellent performance.

Magnetic Sensors

In the research and development of magnetic sensors, dysprosium-iron alloy plays an important role. Leveraging its sensitivity to magnetic field changes, high-precision magnetic sensors can be manufactured. These sensors are used to detect variations in magnetic field strength and direction, as well as physical quantities such as displacement and velocity of objects. They have significant application value in industrial automation control, intelligent transportation monitoring, and aerospace fields, enabling precise measurement and control of relevant physical quantities.

Electronics Industry

Electronic Component Manufacturing

In the production of electronic components such as electronic transformers and inductors, dysprosium-iron alloy can be processed to extract dysprosium for the manufacture of dysprosium-containing components. These components exhibit unique electromagnetic properties, such as high magnetic permeability and low magnetic loss, which meet the demands of modern electronic devices for miniaturization and high performance. They are widely used in various electronic devices, including smartphones, computers, and communication base stations, enhancing the electromagnetic performance and overall efficiency of the devices.

Laser Technology

Laser Crystal Doping

In laser technology, dysprosium-iron alloy serves as an important source of dysprosium for doping laser crystals. For example, in specific laser crystals, the addition of dysprosium allows the generation of laser beams with specific wavelengths upon external energy excitation. These lasers are used in multiple fields, including laser medicine (e.g., laser surgery, laser therapy), laser processing (e.g., cutting, welding), and laser communication. This expands the application scope of laser technology and improves the effectiveness and efficiency of related operations.

Steel Industry

Improving Steel Performance

Adding an appropriate amount of dysprosium-iron alloy to the production of alloy steel and stainless steel allows dysprosium to combine elements such as carbon and nitrogen in the steel to form fine, dispersed compounds. These compounds effectively hinder dislocation movement in the steel under stress, significantly enhancing the steel’s strength and toughness. This enables the steel to maintain high strength while resisting brittle fracture under high loads and impact, expanding its application range in fields such as construction and mechanical manufacturing and improving the quality and performance of steel products.

Medical Field

Medical Imaging and Diagnostic Assistance

Dysprosium in dysprosium-iron alloy has unique physicochemical properties. In the field of medical imaging, it can be used as a potential contrast agent component or auxiliary diagnostic material after special processing. For example, in the development of new medical imaging technologies, the special signal changes produced by the interaction of dysprosium with human tissues can help doctors more clearly and accurately observe pathological tissues and diagnose conditions. This provides strong support for early disease diagnosis and precise treatment. However, these applications are still in the stage of further exploration and development.