Terbium

Melting and Boiling Points

Terbium has a melting point of 1356°C and a boiling point of 3230°C. The high melting point allows it to maintain its solid state and undergo processing at elevated temperatures, while the high boiling point ensures its stability in high-temperature environments. This makes it suitable for various industrial applications that require high-temperature processing or usage, providing a solid thermal foundation for its applications.

Density and Hardness

Terbium has a density of approximately 8.23 g/cm³ and a moderate hardness, with a Mohs hardness of around 4.5. It possesses adequate mechanical properties, allowing it to withstand certain external forces during processing and can be shaped through conventional methods such as forging and rolling to meet the requirements of different production processes.

Ductility and Electrical Conductivity

Terbium exhibits a certain degree of ductility, enabling it to be processed into various shapes such as thin sheets and fine wires, facilitating subsequent industrial applications. As a metallic conductor, its electrical conductivity is somewhat weaker than that of common metals like copper and aluminum, but it can still meet the requirements of some industrial applications where high electrical conductivity is not essential.

Oxidation States and Reactivity

The common oxidation states of terbium in compounds are +3 and +4. It is chemically reactive and can react with oxygen in the air at room temperature to form an oxide layer on its surface, which to some extent slows down further oxidation. Under heated conditions or when in contact with acids or bases, terbium undergoes noticeable chemical reactions.

Reaction with Acids and Bases

Terbium can react with common acids such as dilute hydrochloric acid and dilute sulfuric acid to form corresponding terbium salts (e.g., terbium chloride, terbium sulfate) while releasing hydrogen gas. It also reacts with alkaline solutions, demonstrating the characteristics of a reactive metal in acid-base reactions and following the general patterns of reactions between active metals and acids or bases.

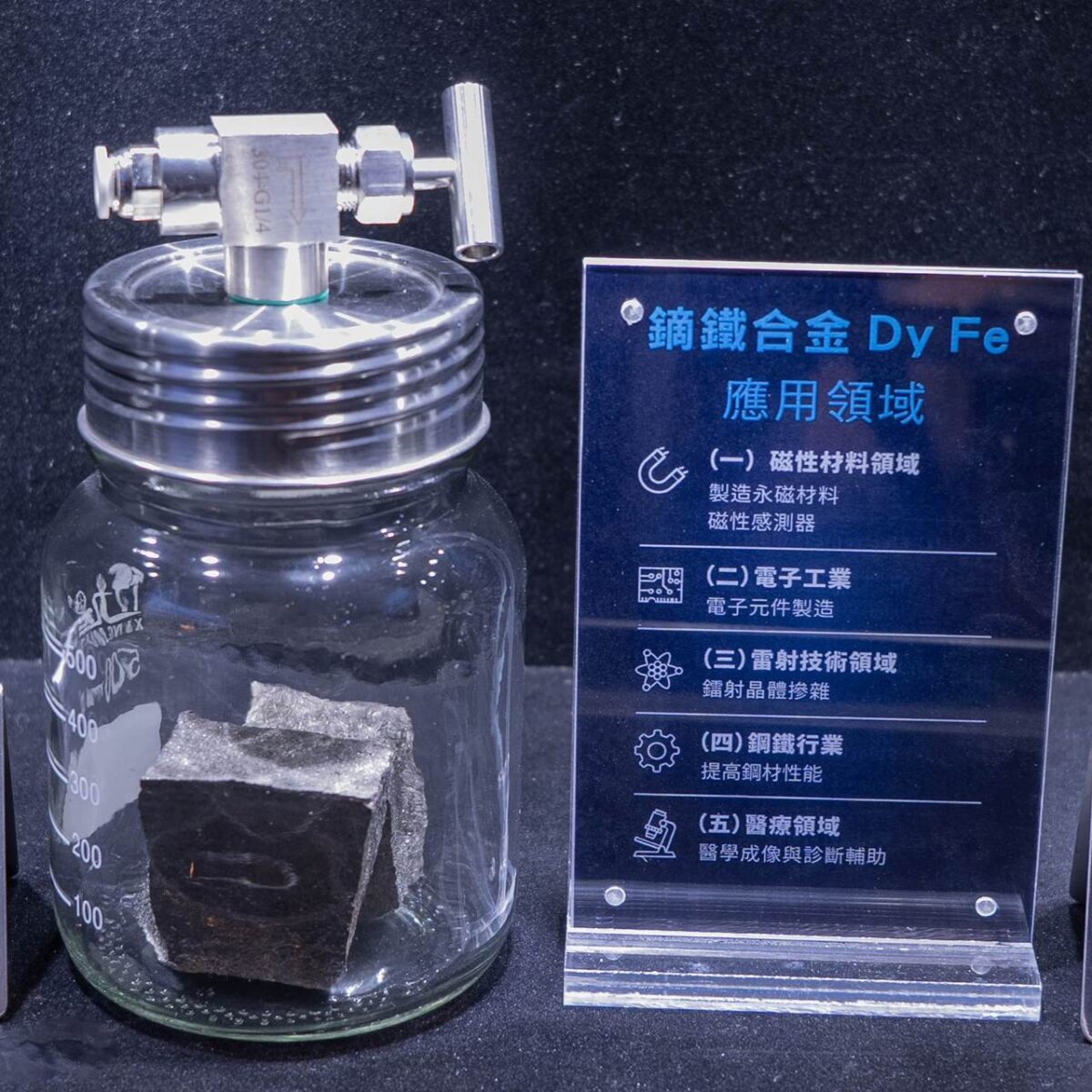

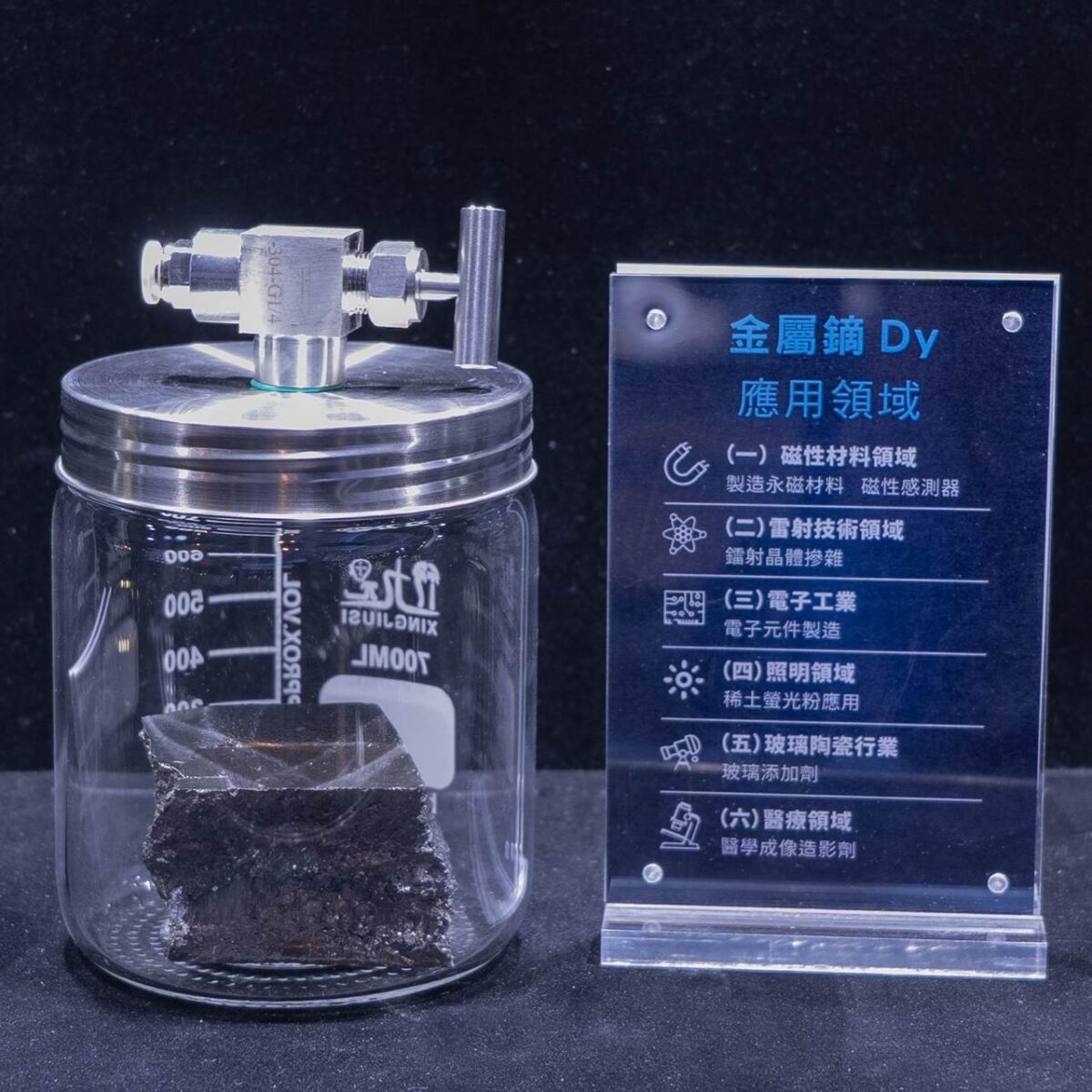

Magnetic Materials Field

Manufacturing Permanent Magnets

Terbium is one of the key elements in the production of high-performance permanent magnets. Adding an appropriate amount of terbium to neodymium-iron-boron (NdFeB) permanent magnets significantly enhances the coercivity of the magnets and improves their magnetic performance stability at high temperatures. This enables permanent magnets to be widely used in various fields with extremely high requirements for magnetic field strength and stability, such as electric vehicle motors, wind turbine generators, high-precision industrial motors, and aerospace equipment motors. These applications ensure stable and efficient operation of the equipment under complex conditions and in high-temperature environments.

Magnetic Sensors

Leveraging its unique magnetic properties, terbium can be used to manufacture magnetic sensors. These sensors are capable of sensitively detecting changes in magnetic field strength and direction, thereby measuring physical quantities such as displacement and velocity of objects. They are important in fields such as industrial automation control, intelligent transportation monitoring, and robotics, helping to achieve precise measurement and control, and enhancing the efficiency and accuracy of system operations.

Luminescent Materials Field

Phosphor Applications

Terbium is an important component in the production of high-performance phosphor. In some rare earth phosphors, terbium, when combined with other elements, can emit bright and efficient light of specific colors (such as green) upon excitation by external energy (e.g., ultraviolet light). These phosphors are used in lighting and display products such as fluorescent lamps, LED lights, and flat-panel displays, effectively improving the color rendering and visual effects of the products and creating a better lighting and viewing environment for people.

Electronics Industry

Manufacturing Electronic Components

In the production of certain electronic components (such as electronic transformers and inductors), terbium can be used as a raw material to manufacture terbium-containing electronic components through further processing. These components often possess unique electromagnetic properties, such as high magnetic permeability and low magnetic loss, which meet the demands of modern electronic devices for miniaturization and high performance. They are widely used in various electronic devices, including smartphones, computers, and communication base stations, contributing to the overall performance improvement of the devices.

Laser Technology Field

Laser Crystal Doping

Terbium can be used as a key doping element in laser crystals. For example, in certain laser crystals, doping with terbium allows the generation of laser beams of specific wavelengths upon excitation by external energy. These lasers are applied in various fields, including laser medicine (e.g., laser surgery, laser therapy), laser processing (e.g., cutting, welding), and laser communication. This helps to expand the application range of laser technology and improve the effectiveness and efficiency of related operations.

Medical Field

Medical Imaging Contrast Agents

Certain compounds of terbium have potential applications in medical imaging. After special processing, they may be used as contrast agents to help doctors more clearly observe internal body tissues and pathological conditions. However, most of these applications are currently in the research and exploration stages and have not yet been widely used in clinical practice.

Glass and Ceramic Industry

Glass Additives

In glass manufacturing, adding terbium to optical glass can absorb specific wavelengths of light and alter the optical properties of the glass. It is used in the production of optical components such as color filters and polarizing lenses. In architectural glass, terbium can enhance radiation resistance, making it suitable for special environments, such as observation windows in nuclear power plants. In ceramic production, terbium improves the color, hardness, and high-temperature resistance of ceramics, enhancing the quality of ceramic products and is commonly used in the manufacture of high-end ceramics.