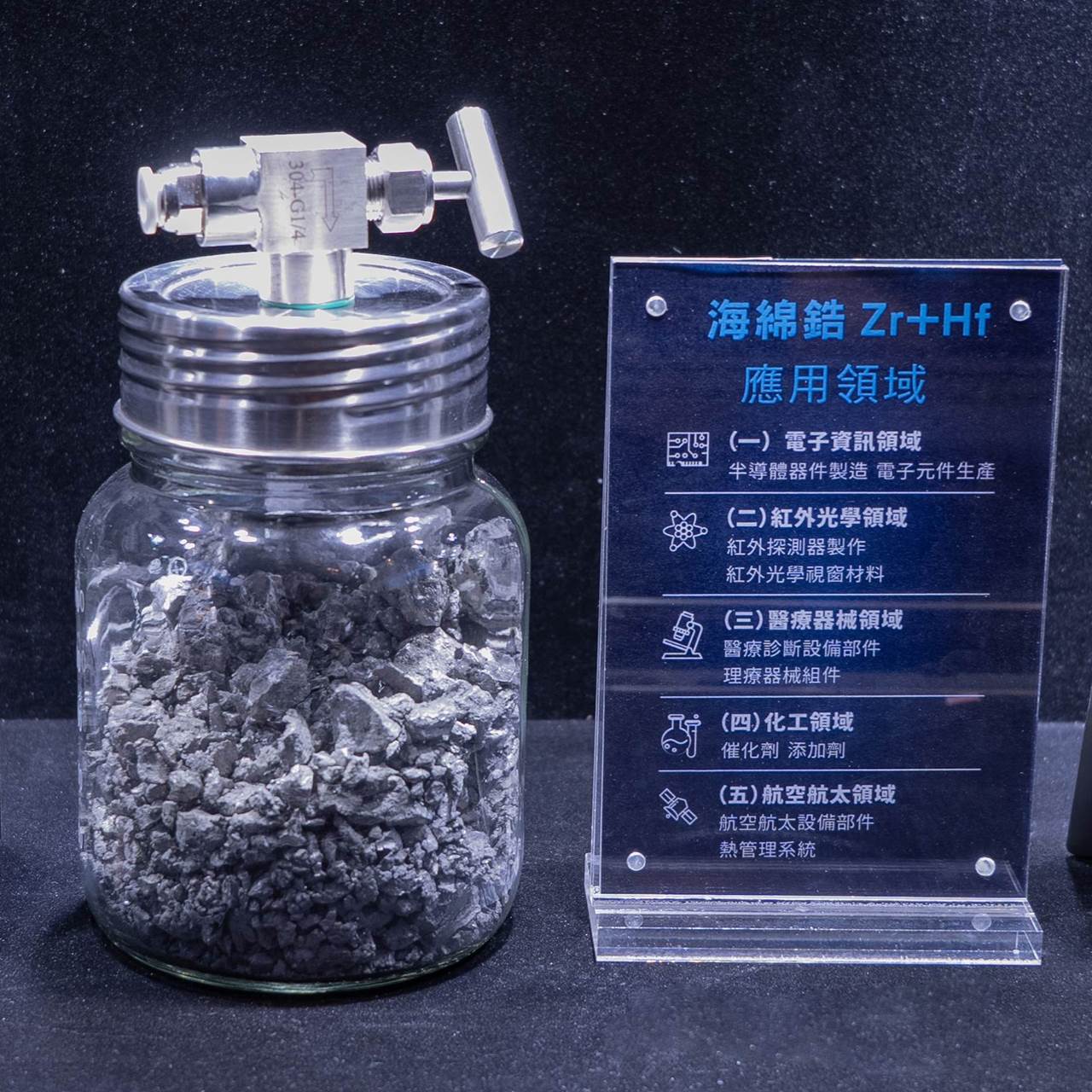

Melting and Boiling Points

Sponge zirconium has a high melting point of around 1852°C and a boiling point of up to 4377°C. These high-temperature characteristics provide it with excellent high-temperature resistance, allowing it to maintain a stable physical state in high-temperature environments. This forms the basis for its application in many high-temperature-related fields.

Density and Hardness

Its density is approximately 6.5 g/cm³. In terms of hardness, it has a Mohs hardness of around 4-5. This endows it with certain mechanical properties, enabling it to withstand external forces during subsequent processing and facilitating shaping for various industrial applications.

Ductility and Electrical Conductivity

Sponge zirconium has a certain degree of ductility, which allows it to be processed into different shapes, such as sheets and wires, through methods like rolling and forging. It is also a good conductor of electricity, with a certain level of electrical conductivity, making it suitable for applications where electrical conductivity is required.

Oxidation States and Reactivity

The common oxidation state of zirconium in compounds is +4. At room temperature, sponge zirconium is relatively chemically stable, forming a thin oxide film on its surface. This film helps protect the underlying metallic zirconium from erosion by air and water. However, under special conditions such as high temperatures and strong oxidizing environments, it can react with oxygen to form zirconium oxides.

Reactions with Acids and Bases

At room temperature, sponge zirconium has good resistance to common acids such as hydrochloric acid and sulfuric acid, with slow reaction rates. However, it can react with strong oxidizing acids like nitric acid and aqua regia. In alkaline solutions, it is relatively stable, although it can be corroded to some extent under extreme conditions such as high temperatures and high-concentration alkali solutions.

Aerospace Field

Manufacturing High-Performance Structural Components

Key structural components of aerospace vehicles, such as engines and fuselage frames, need to operate reliably in high-temperature, high-pressure, high-stress, and complex space environments. Sponge zirconium can be further processed into various zirconium alloys, which can be added to nickel-based and titanium-based alloy systems. This significantly enhances the high-temperature strength, creep resistance, oxidation resistance, and fatigue resistance of the alloys, ensuring the normal operation of these critical components in harsh environments and guaranteeing the flight safety and overall performance of aerospace vehicles. For example, components such as turbine blades in aero engines are made from high-performance alloys containing zirconium.

Protective Layers for Spacecraft

In the outer protective layers of spacecraft, materials made from sponge zirconium can effectively withstand threats from the space environment, such as high temperatures, radiation, and micrometeoroid impacts. Its high-temperature resistance and radiation resistance provide good protection for the equipment inside the spacecraft and the astronauts, extending the service life of the spacecraft and ensuring the smooth progress of space missions.

Nuclear Energy Field

Key Components of Nuclear Reactors

In nuclear power generation facilities, zirconium alloys processed from sponge zirconium are important materials for the cladding of nuclear reactor fuel rods. They have excellent radiation resistance, high-temperature resistance, corrosion resistance, and a low neutron absorption cross-section. These properties effectively seal the nuclear fuel inside, preventing leakage and ensuring the safe and stable operation of the nuclear fission reaction during long-term operation of the nuclear reactor. They play a crucial role in the safe and reliable operation of the entire nuclear energy utilization system.

Facilities for Nuclear Waste Treatment

In the construction of nuclear waste storage and treatment facilities, materials related to sponge zirconium can also be used. For example, they can be used to manufacture corrosion-resistant and radiation-resistant containers or structural components, which help safely manage and dispose of nuclear waste, reducing potential environmental hazards.

Chemical Industry

Corrosion-Resistant Reaction Equipment

In chemical production, which often involves corrosive media and high-temperature, high-pressure processes, sponge zirconium can be processed into equipment such as chemical reactors, heat exchangers, and pipelines. Leveraging its excellent corrosion resistance (especially to strong acids and alkalis) and high-temperature stability, it ensures the safe, stable, and efficient operation of chemical production processes. It is suitable for many chemical fields, such as the chlor-alkali industry and petrochemicals.

Catalyst Supports

In some chemical reactions, sponge zirconium can be used as a catalyst support, loading active metal catalysts onto its porous structure. This enhances the activity, stability, and dispersion of the catalyst, thereby accelerating chemical reaction rates and improving the quality of chemical products. It has good application prospects in processes such as organic synthesis and hydrogenation reactions.

Electronics Industry

Manufacturing Electronic Components

In the manufacturing of some electronic components, such as ceramic capacitors and electron tubes, sponge zirconium can be processed into components like electrodes and casings. Utilizing its good electrical conductivity, high-temperature resistance, and chemical stability, it helps improve the performance and reliability of electronic components. This meets the demand for miniaturization and high performance in electronic devices and is widely used in many electronic products, such as smartphones, computers, and communication equipment.

Medical Device Field

Medical Implants

Due to its good biocompatibility, mechanical properties, and corrosion resistance, sponge zirconium can be processed and surface-modified to potentially be used in the manufacture of medical implants, such as artificial joints and dental implants. It offers the possibility of providing high-performance, safe, and reliable medical device products for patients. However, its application in this area is still in the stage of further development and expansion.

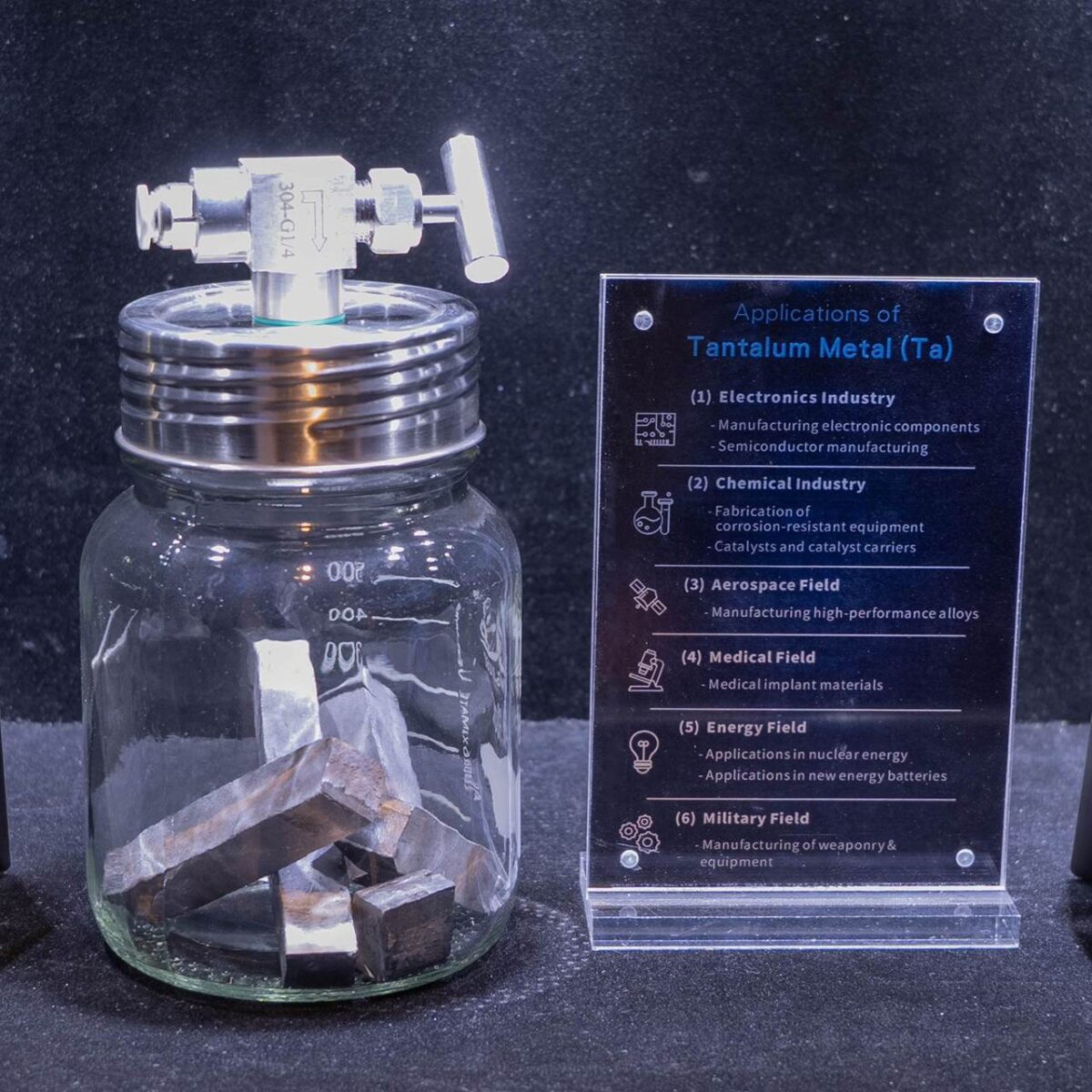

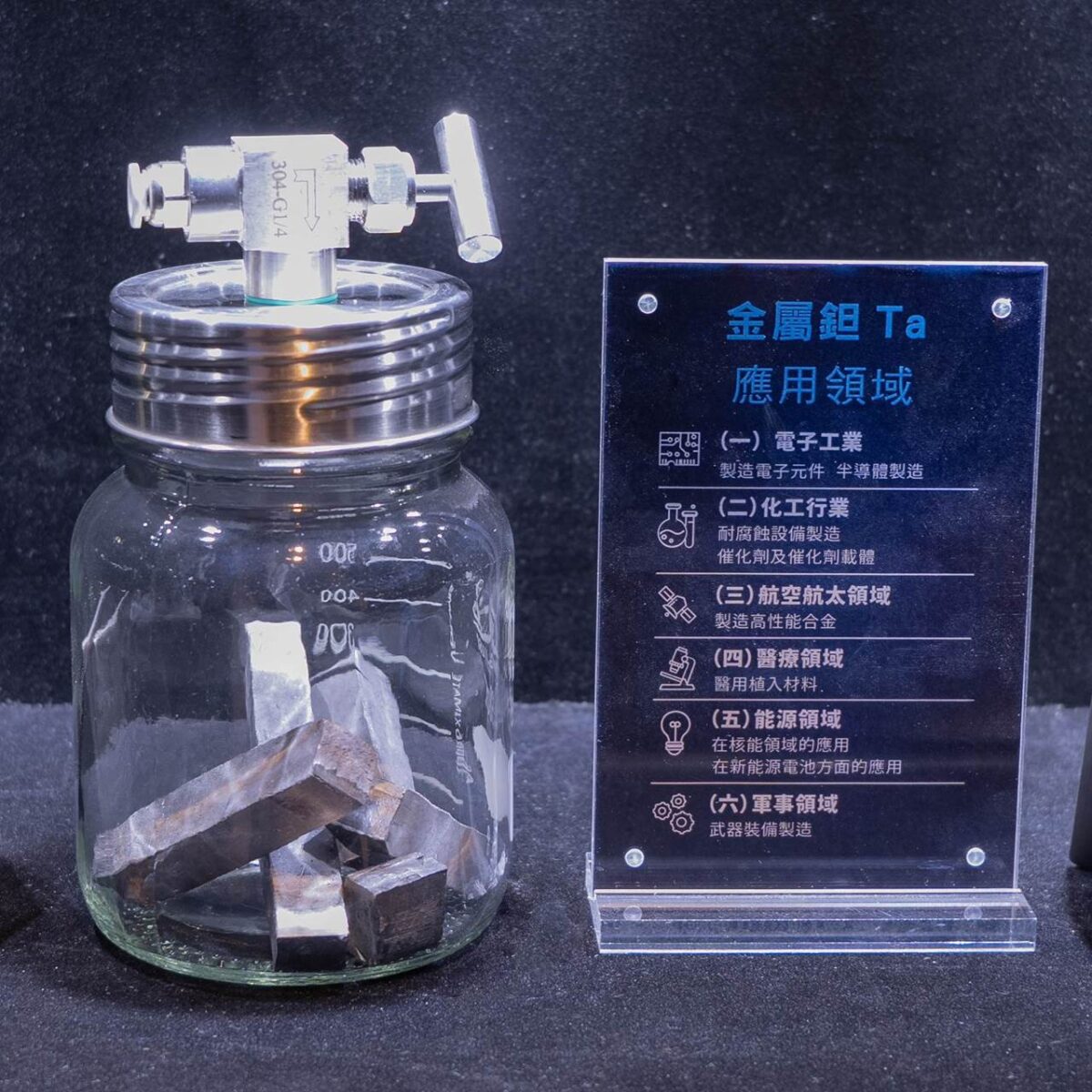

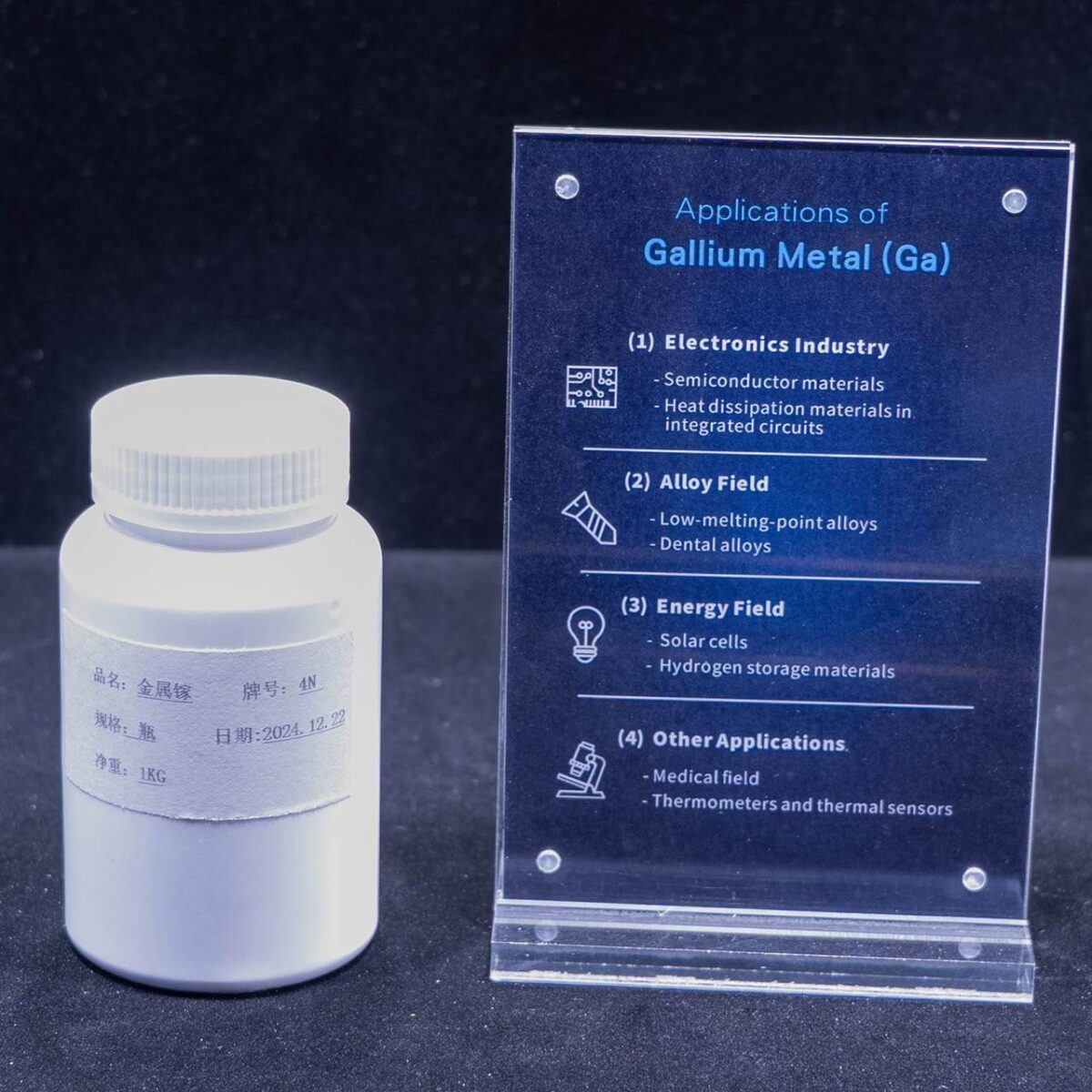

Related products

Rare Metals

Rare Metals

Rare Metals

Rare Metals