Holmium-Iron Alloy

Melting and Boiling Points

Holmium-iron alloy has a relatively high melting point, generally between 1300°C and 1500°C, and a similarly high boiling point. This gives it excellent high-temperature stability, making it suitable for high-temperature processing and industrial applications that require thermal stability.

Density and Hardness

The density of holmium-iron alloy is higher than that of pure iron, typically ranging from 7.5 to 8.5 g/cm³. Its hardness is also slightly higher than that of pure iron, providing it with good mechanical properties. This makes it suitable for forging, rolling, and other processing operations, allowing for shape modifications based on practical application needs.

Ductility and Electrical Conductivity

Holmium-iron alloy exhibits a certain degree of ductility, although it is relatively weaker compared to some common metals. In terms of electrical conductivity, it is a metallic conductive material. The addition of holmium alters its electrical conductivity compared to pure iron, making it suitable for specific industrial applications that require certain conductive properties.

Oxidation States and Reactivity

Holmium commonly exhibits a +3 oxidation state in compounds. In holmium-iron alloy, holmium interacts with iron and other impurity elements, resulting in good overall chemical stability. At room temperature, holmium-iron alloy does not undergo significant chemical reactions in normal environments. However, under high temperatures or strong oxidizing conditions, holmium can gradually oxidize, forming corresponding holmium oxides.

Reactions with Acids and Bases

Holmium-iron alloy can react with strong acids, such as dilute hydrochloric acid and dilute sulfuric acid. In these reactions, holmium and iron enter the solution in ionic form, and hydrogen gas is produced. In alkaline solutions, the alloy is relatively stable, although under extreme conditions such as high temperatures or high-concentration alkaline solutions, some degree of corrosion may occur.

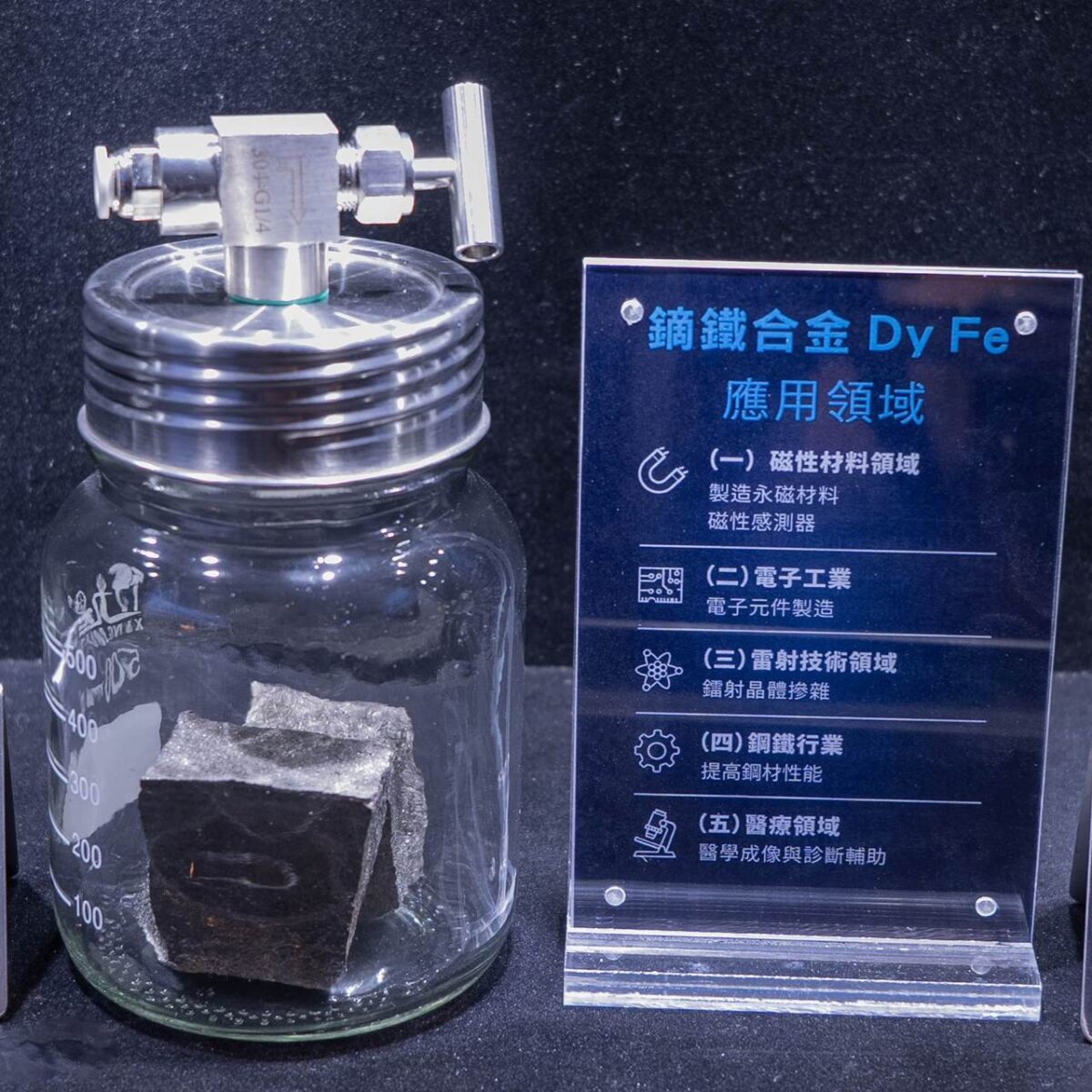

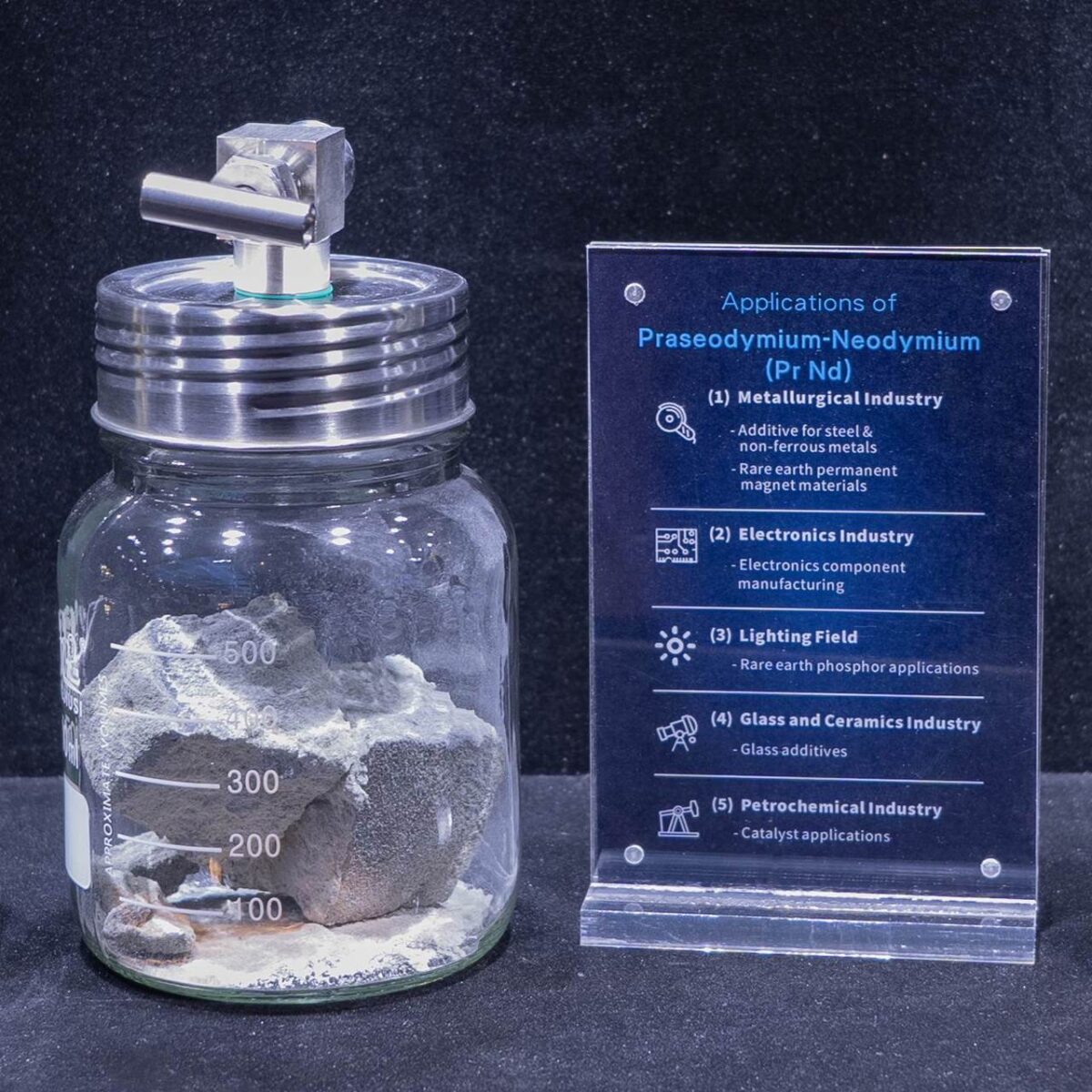

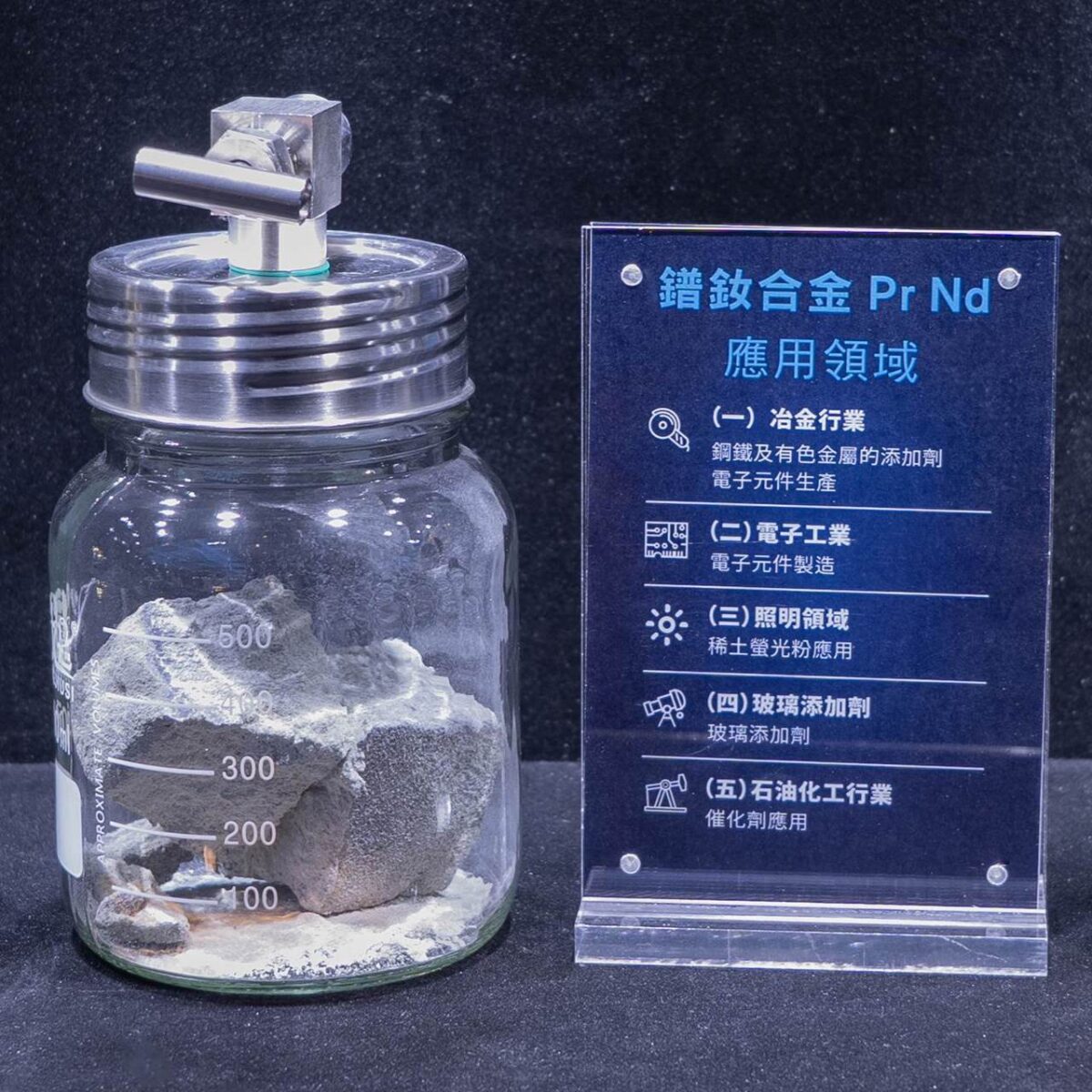

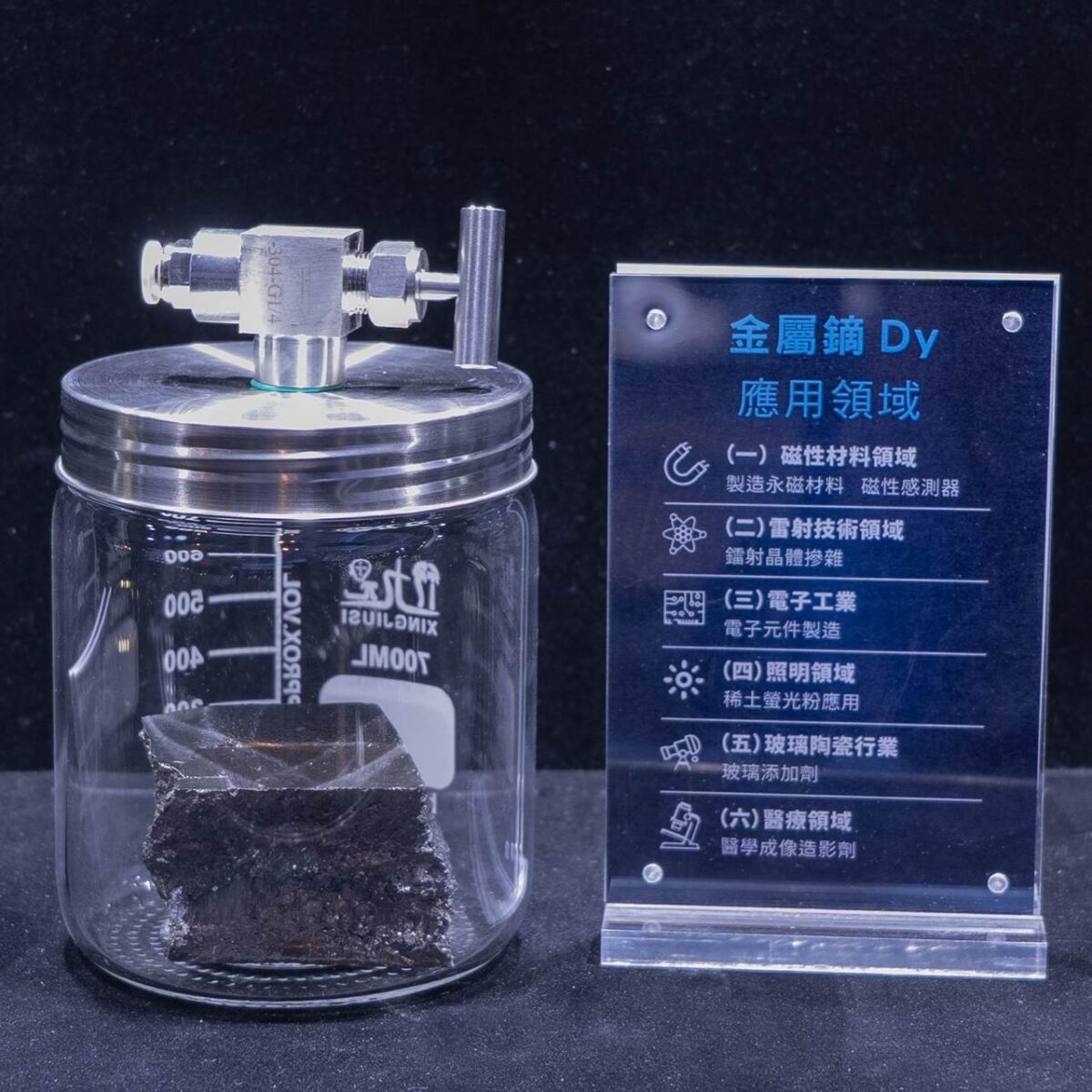

Magnetic Materials

Production of Permanent Magnets

Holmium is a magnetic rare earth element. After specific processing and magnetization, holmium-iron alloy can be used to manufacture permanent magnets. These magnets are important in devices that require high magnetic field strength and stability, such as small motors, high-precision instruments, and certain specialized speakers. They provide stable and suitable magnetic fields, contributing to the devices’ performance and precision.

Magnetic Sensor Applications

Holmium-iron alloy also plays a role in the development and manufacturing of magnetic sensors. Leveraging its magnetic properties and sensitivity to changes in magnetic fields, holmium-iron can be used to create sensors that detect magnetic field strength, direction, and changes in physical quantities such as displacement and velocity. These sensors are used in industrial automation, intelligent traffic monitoring, aerospace, and other fields, providing critical detection data for the precise operation of related systems.

Laser Technology

Laser Crystal Doping

In laser technology, holmium-iron alloy serves as an important source of holmium for doping laser crystals. For example, in holmium-doped laser crystals, specific wavelengths of laser light can be generated under external energy excitation. These lasers are used in medical applications (e.g., laser surgery, laser therapy), laser processing (e.g., cutting, welding), and laser communication, expanding the application range of laser technology and improving the effectiveness and efficiency of related applications.

Steel Industry

Enhancing Steel Properties

In the production of alloy steels and stainless steels, the addition of holmium-iron alloys can improve the properties of the steel. Holmium combines carbon, nitrogen, and other elements in the steel to form fine, dispersed compounds. These compounds effectively hinder dislocation movement under stress, significantly increasing the strength and toughness of the steel. This allows the steel to maintain high strength and resist brittle fracture under heavy loads or impact, expanding its applications in construction, machinery manufacturing, and other fields, and improving the quality and performance of steel products.

Medical Field

Medical Imaging and Diagnostic Assistance

Holmium in holmium-iron alloy possesses unique physical and chemical properties that make it a potential component of contrast agents or diagnostic materials in medical imaging. For example, in the development of new medical imaging technologies, the interaction between holmium and human tissues can produce special signal changes, potentially helping doctors observe lesions more clearly and accurately, and aiding in early diagnosis and precise treatment of diseases. However, these applications are still in the exploratory and developmental stages.