• It has a high melting point, around 1660°C, which allows it to maintain excellent physical stability under high-temperature conditions.

• Due to the presence of titanium, the alloy possesses a certain degree of oxidation resistance in air. Titanium forms a dense oxide layer (primarily TiO₂) on the surface, preventing further oxidation of the iron and other elements within the alloy, thereby enhancing its corrosion resistance.

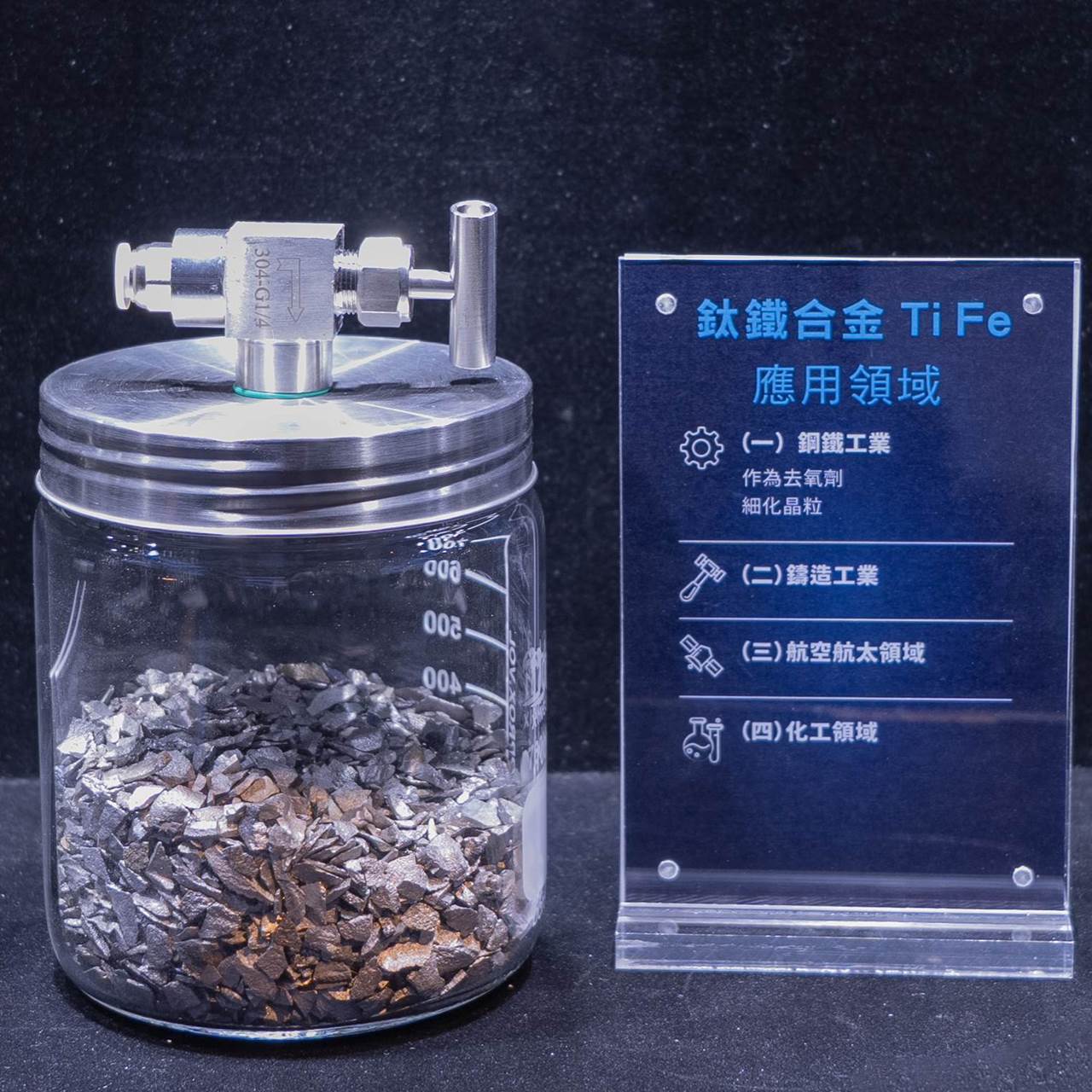

Steel Industry

As a Deoxidizer

In steelmaking, titanium-iron alloy is used for deoxidation. Oxygen dissolved in molten steel can adversely affect the quality of the steel, leading to issues such as porosity and reduced toughness. Titanium has a strong affinity for oxygen, allowing it to remove oxygen from the molten steel through the reaction Ti + O₂ = TiO₂. The resulting TiO₂ and other oxides float to the surface of the molten steel and can be removed.

Grain Refinement

Titanium-iron alloy can also refine the grain structure of steel. Titanium forms fine particles such as carbides and nitrides (e.g., TiC, TiN), which are distributed throughout the steel matrix. These particles inhibit grain growth during heating and cooling processes. Refined grains significantly improve the strength, toughness, and plasticity of the steel. For example, in the production of high-strength alloy steels, adding an appropriate amount of titanium-iron alloy can increase the yield strength by 30%-50% while also improving impact toughness.

Casting Industry

• Additionally, titanium-iron alloy enhances the wear resistance and corrosion resistance of castings. For castings operating in harsh environments, such as pump bodies and valves in seawater or corrosive media, the service life can be extended by 2-3 times with the addition of titanium-iron alloy.

Aerospace Industry

• Furthermore, titanium-iron alloy is used in structural components such as spacecraft shells. Its relatively low density helps reduce the weight of the spacecraft while maintaining structural strength, thereby improving payload capacity and flight performance.

Chemical Industry

• For example, in the chlor-alkali industry, certain components of electrolytic cells used to produce chlorine and caustic soda are made from titanium-iron alloy. During the electrolysis process, the anode generates highly oxidizing chlorine gas, and titanium-iron alloy can resist chlorine corrosion, ensuring the normal operation of the electrolytic cells.

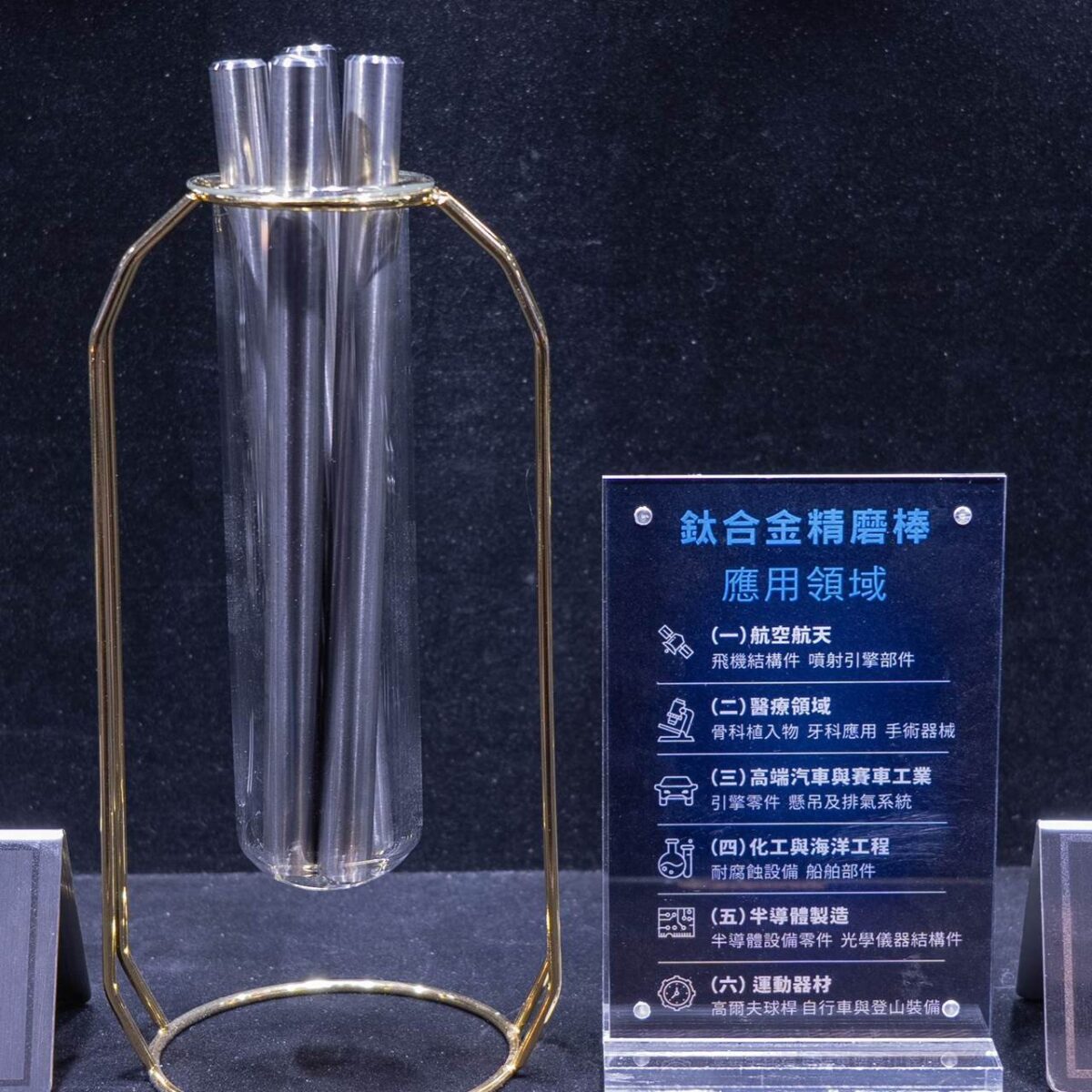

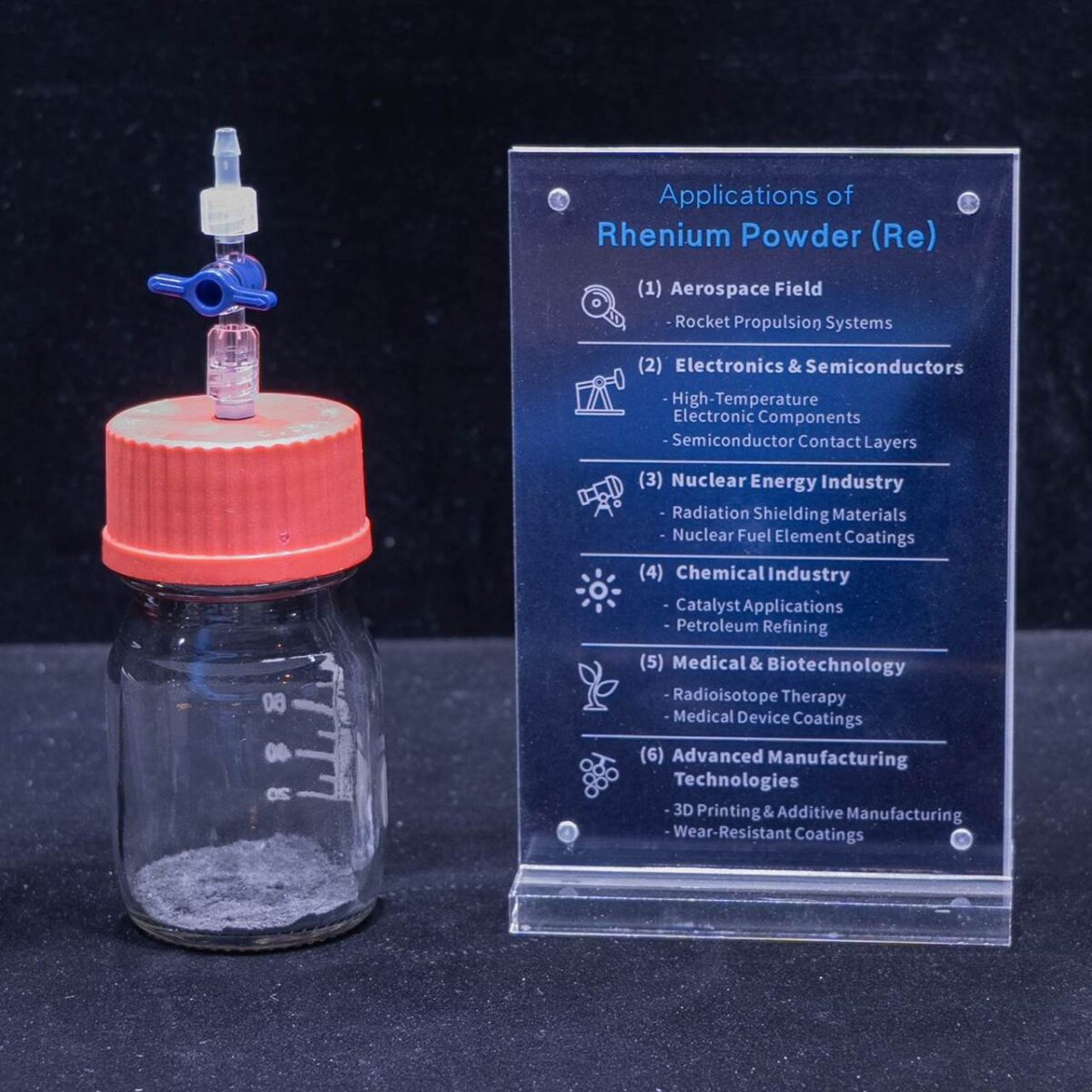

Related products

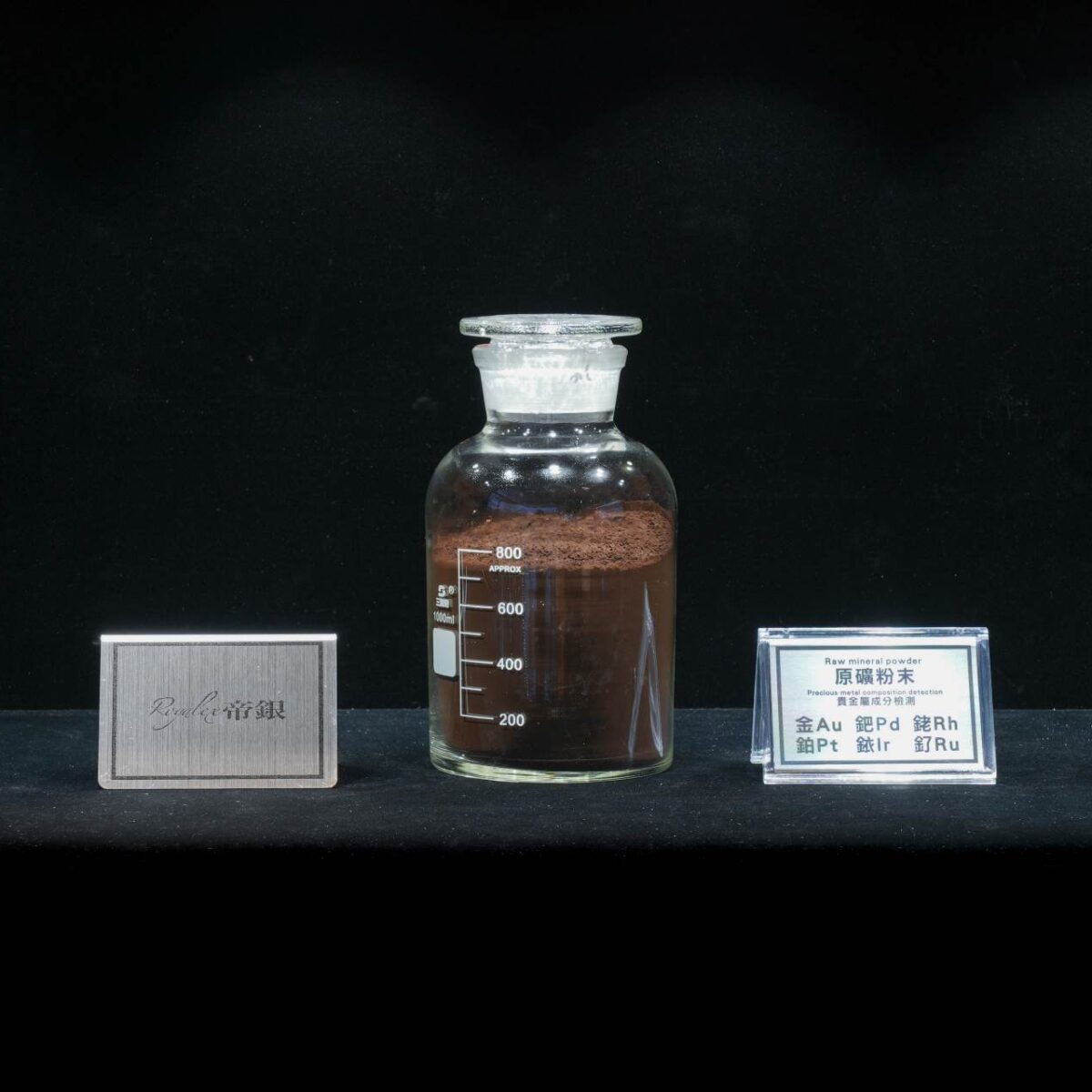

Rare Metals

Rare Metals

Rare Metals

Rare Metals