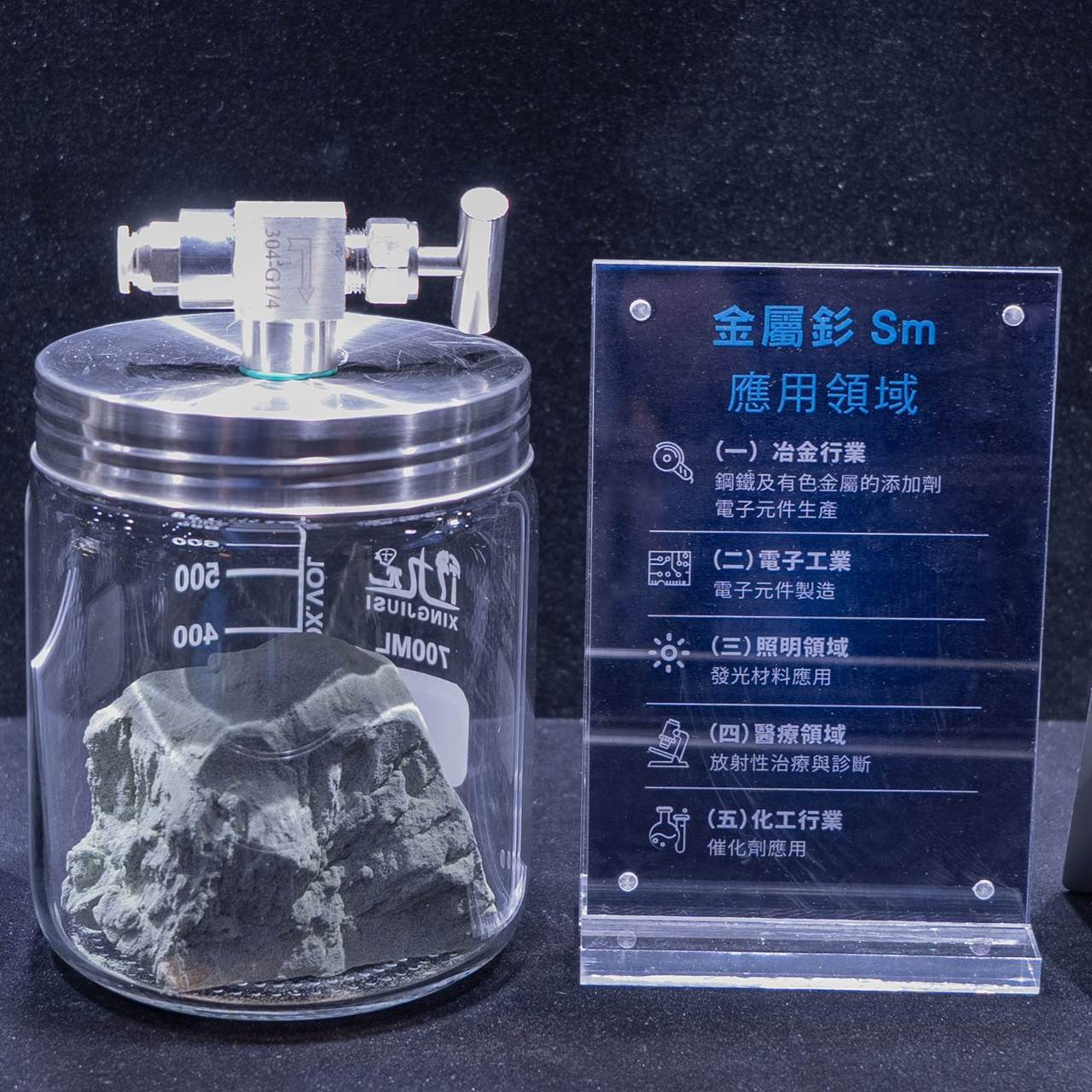

Samarium

Melting and Boiling Points

Samarium has a melting point of 1074°C and a boiling point of 1794°C. This range of melting and boiling points allows it to exhibit certain characteristics in high-temperature environments, making it suitable for applications that require medium to high-temperature processing and use, providing a basis for its industrial applications.

Density and Hardness

With a density of about 7.52 g/cm³ and a relatively low hardness (approximately 2.5 on the Mohs scale), samarium is quite soft. This makes it relatively easy to deform in some processing techniques, such as being conveniently processed into powders, thin sheets, and other forms.

Ductility and Electrical Conductivity

Samarium has a certain degree of ductility, allowing for moderate stretching, rolling, and other deformation processes. However, compared to some common metals, their ductility is slightly weaker. It is a metallic conductor, although its electrical conductivity is not as good as that of some commonly used conductive metals (such as copper and aluminum), it can still meet the needs of some applications where electrical conductivity is not particularly high.

Oxidation States and Reactivity

The common oxidation states of samarium in compounds are +2 and +3. It is chemically active and can react with oxygen in the air at room temperature, gradually forming an oxide film on the surface to slow down further oxidation. Under specific conditions such as heating, contact with acids or bases, samarium will react more quickly.

Reactions with Acids and Bases

Samarium can react with common acids such as diluting hydrochloric acid and diluting sulfuric acid to form corresponding samarium salts (such as samarium chloride, samarium sulfate, etc.) and release hydrogen gas. When in contact with alkaline solutions, it will also undergo chemical reactions, demonstrating the chemical activity of an active metal. Its chemical behavior in reactions conforms to the general rules of active metals reacting with acids and bases.

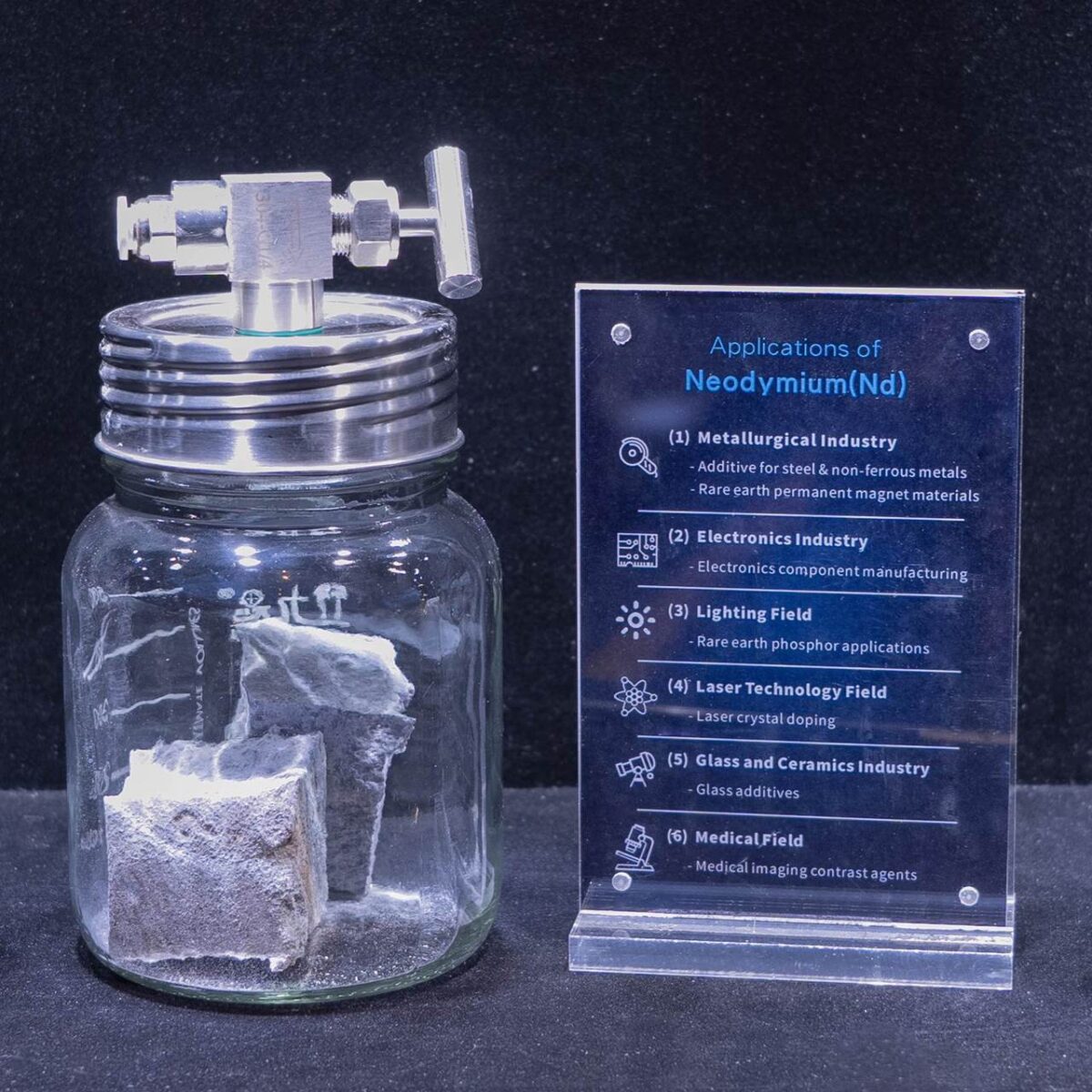

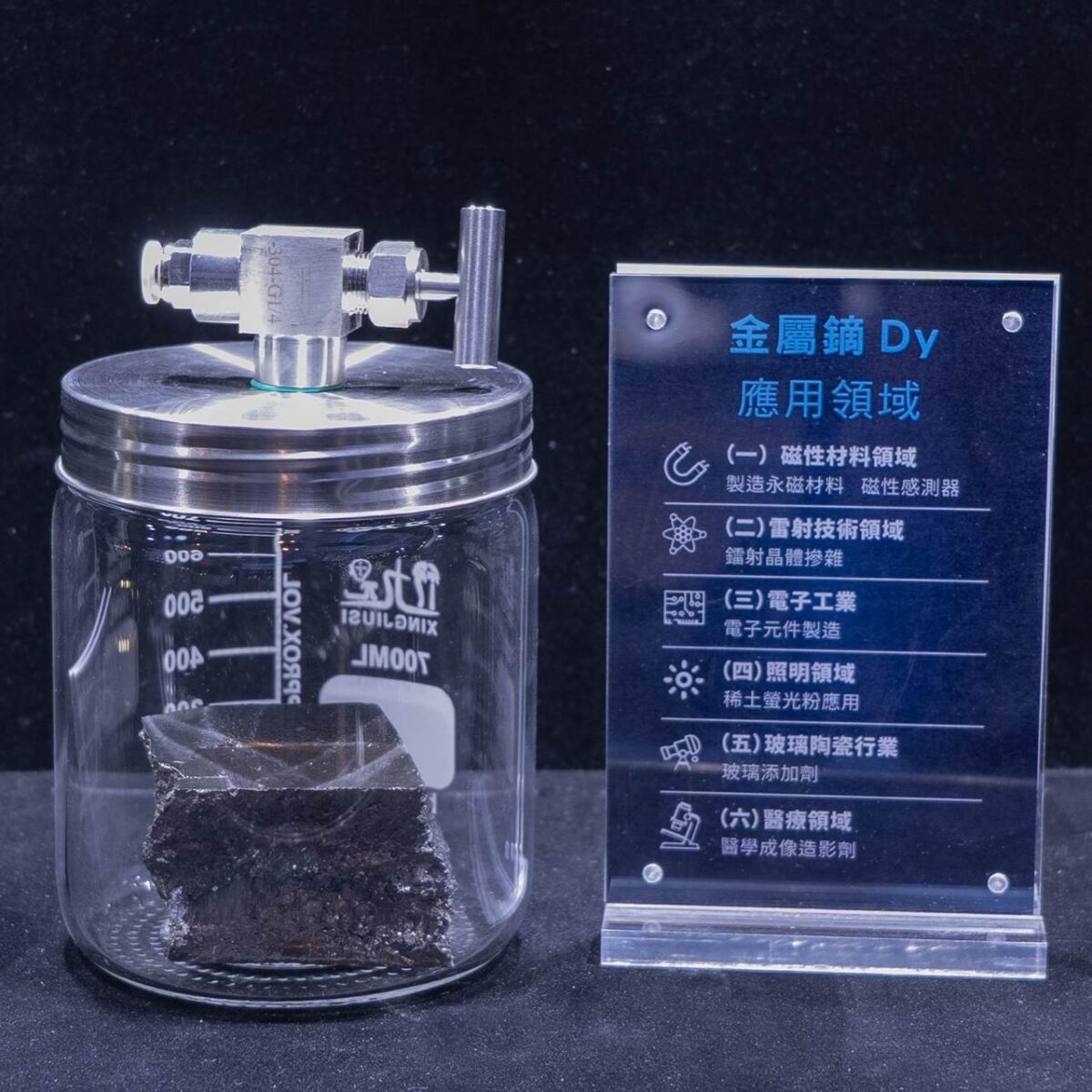

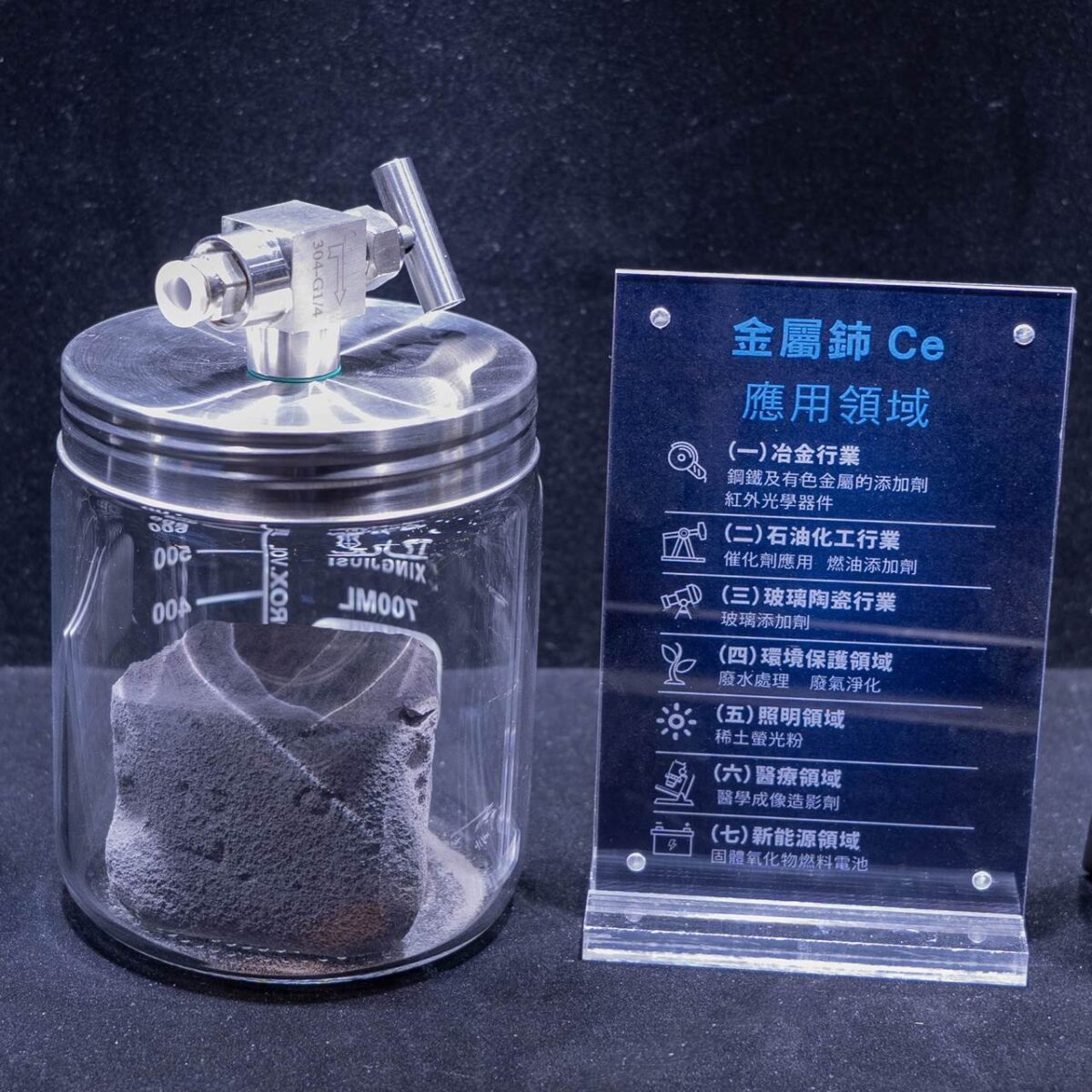

Metallurgical Industry

Additives in Steel and Nonferrous Metals

In steel production, the addition of an appropriate amount of samarium can serve as a deoxidizer and desulfurizer, helping to purify the steel melt and thereby improve the quality of steel. Moreover, samarium can refine the grain size of steel, enhancing its toughness, wear resistance, and corrosion resistance, allowing steel to perform better in fields such as construction and mechanical manufacturing. Adding samarium to nonferrous metals such as aluminum and magnesium can also improve their casting properties, mechanical properties, and oxidation resistance. For example, in aluminum alloys, samarium helps increase strength and heat resistance, expanding their range of applications.

Rare Earth Permanent Magnet Materials

Samarium is one of the key elements in the manufacture of high-performance rare earth permanent magnet materials, especially samarium-cobalt permanent magnets (SmCo). These magnets have advantages such as high magnetic energy products, high coercivity, and good temperature stability, and are widely used in motors, generators, aerospace equipment, medical devices, and other fields where high magnetic field strength and stability are required. They provide stable and strong magnetic fields for these devices, ensuring their efficient operation.

Electronic Industry

Manufacturing Electronic Components

In the manufacturing of some electronic components (such as electronic transformers, inductors, etc.), samarium can be used as a raw material for further processing and extraction to manufacture samarium-containing electronic components. These components often have unique electromagnetic properties, such as high magnetic permeability and low magnetic loss, which meet the needs of modern electronic devices for miniaturization and high performance. They are widely used in various electronic devices such as smartphones, computers, and communication base stations.

Lighting Field

Application in Luminescent Materials

Samarium has certain applications in luminescent materials. Its compounds can be used as components of luminescent materials such as phosphors. When combined with other elements, they can emit light from specific colors when excited (such as by ultraviolet radiation) and can be used in lighting products such as fluorescent lamps and LED lights. They play a role in improving light color and increasing luminous efficiency, creating a better lighting environment for people.

Medical Field

Radioactive Therapy and Diagnosis

Some radioactive isotopes of samarium (such as samarium-153) have important applications in the medical field. In radioactive therapy, samarium-153 can be made into radioactive drugs for targeted treatment of diseases such as bone metastatic cancer. The emitted rays can kill cancer cells and alleviate patients’ pain. In medical diagnosis, its radioactive characteristics can help doctors more clearly observe the function and pathological conditions of human internal tissues, providing a basis for accurate disease diagnosis. However, when using radioactive samarium-related drugs, it is necessary to strictly follow relevant safety regulations and operating procedures.

Chemical Industry

Catalyst Applications

Compounds of samarium can act as catalysts in some chemical reactions, such as in organic synthesis reactions and hydrogenation reactions. Samarium-containing catalysts can accelerate reaction rates and improve product quality, helping chemical production to be more efficient and high-quality, and promoting the development of the chemical industry.