Gadolinium-Iron Alloy

Melting and Boiling Points

The melting point of gadolinium-iron alloy is relatively high, usually around 1300°C to 1500°C, and its boiling point is also high. This gives it good high-temperature stability, making it suitable for high-temperature processing and use in high-temperature environments. It can be used in some industrial fields with high thermal stability requirements.

Density and Hardness

Compared with pure iron, the density of gadolinium-iron alloy is increased, generally in the range of 7.5-8.5g/cm³, and its hardness is also higher than that of pure iron. This endows it with good mechanical properties, facilitating forging, rolling, and other processing operations and its shape can be changed according to actual production needs.

Ductility and Electrical Conductivity

Gadolinium-iron alloy has certain ductility, but compared with some common metals, its ductility is slightly weaker. In terms of electrical conductivity, it belongs to metallic conductive materials. The addition of gadolinium elements makes its electrical conductivity different from that of pure iron, which can meet the basic requirements for electrical conductivity in some specific industrial applications.

Oxidation States and Reactivity

The common oxidation state of gadolinium in compounds is +3. In gadolinium-iron alloy, gadolinium interacts with iron and other impurity elements, and the overall chemical stability is good. At room temperature, gadolinium-iron alloy does not undergo obvious chemical reactions in the conventional environment, but under special conditions such as high temperature and strong oxidation, the gadolinium element will gradually be oxidized to form the corresponding gadolinium oxides.

Reactions with Acids and Bases

Gadolinium-iron alloy can react with some strong acids. For example, when reacting with diluted hydrochloric acid and dilute sulfuric acid, gadolinium and iron will enter the solution in the form of ions, accompanied by the generation of hydrogen gas. In alkaline solutions, it is relatively stable, but under extreme conditions such as high temperature and high concentration of alkali, it will also show a certain degree of corrosion and other reaction phenomena.

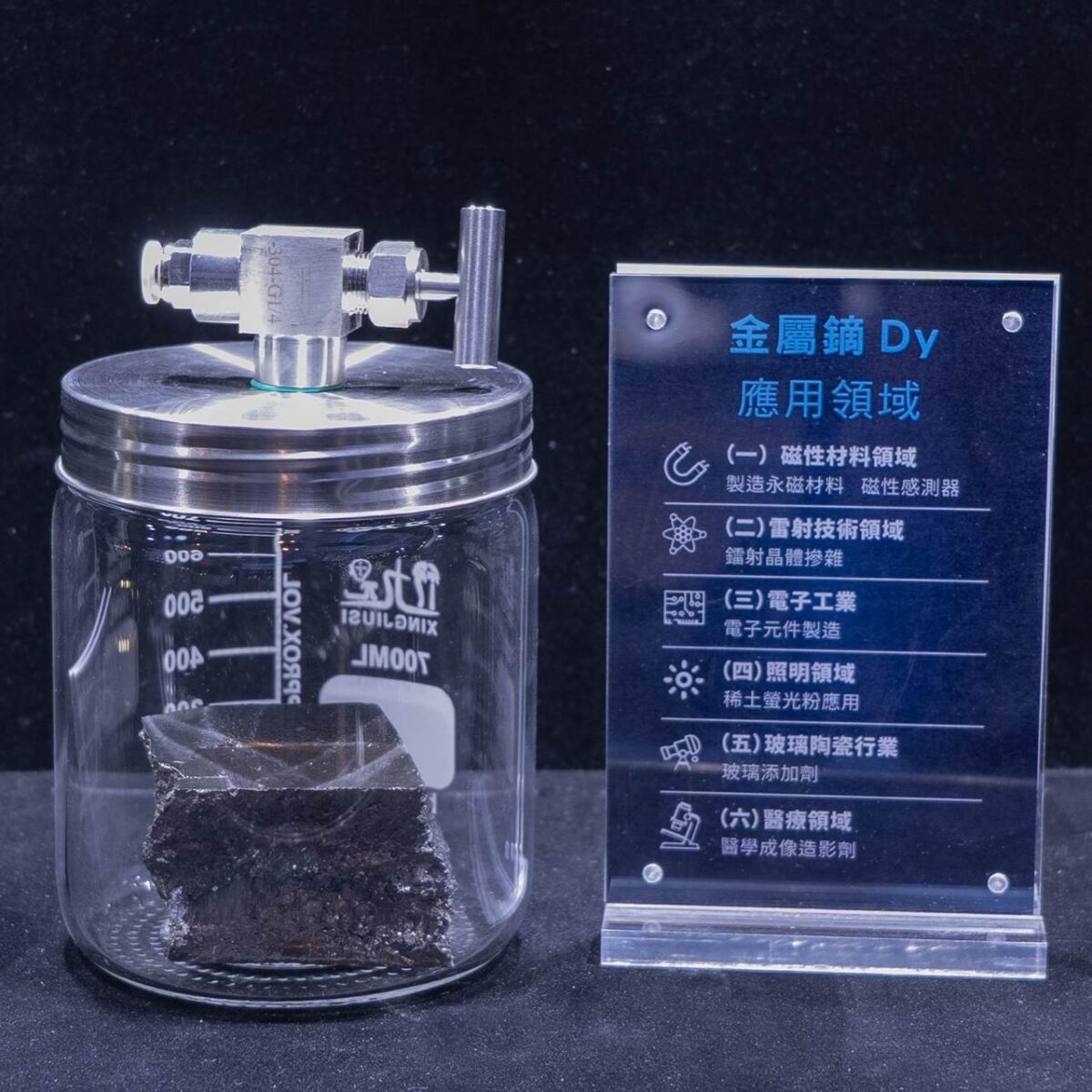

Magnetic Materials Field

Manufacture of Permanent Magnetic Materials

Gadolinium-iron alloy plays an important role in the manufacture of permanent magnetic materials. Gadolinium is an element with strong magnetism. When it combines with iron to form a gadolinium-iron alloy, after specific processing and magnetization treatment, it can be used to manufacture high-performance permanent magnets. These permanent magnets are widely used in equipment that requires high magnetic field strength and high stability, such as motors, generators, and magnetic resonance imaging (MRI) devices, providing stable and strong magnetic fields to ensure the normal operation and good performance of the equipment.

Magnetic Sensors

In the research development and production of magnetic sensors, gadolinium-iron alloy can be used as one of the key materials. Using its magnetic changes to sensitively respond to changes in external magnetic fields and physical quantities, high-precision magnetic sensors can be made to detect changes in magnetic field strength, direction, and physical quantities such as the displacement and velocity of objects. It has important application value in fields such as industrial automation control, automotive electronics, and aerospace.

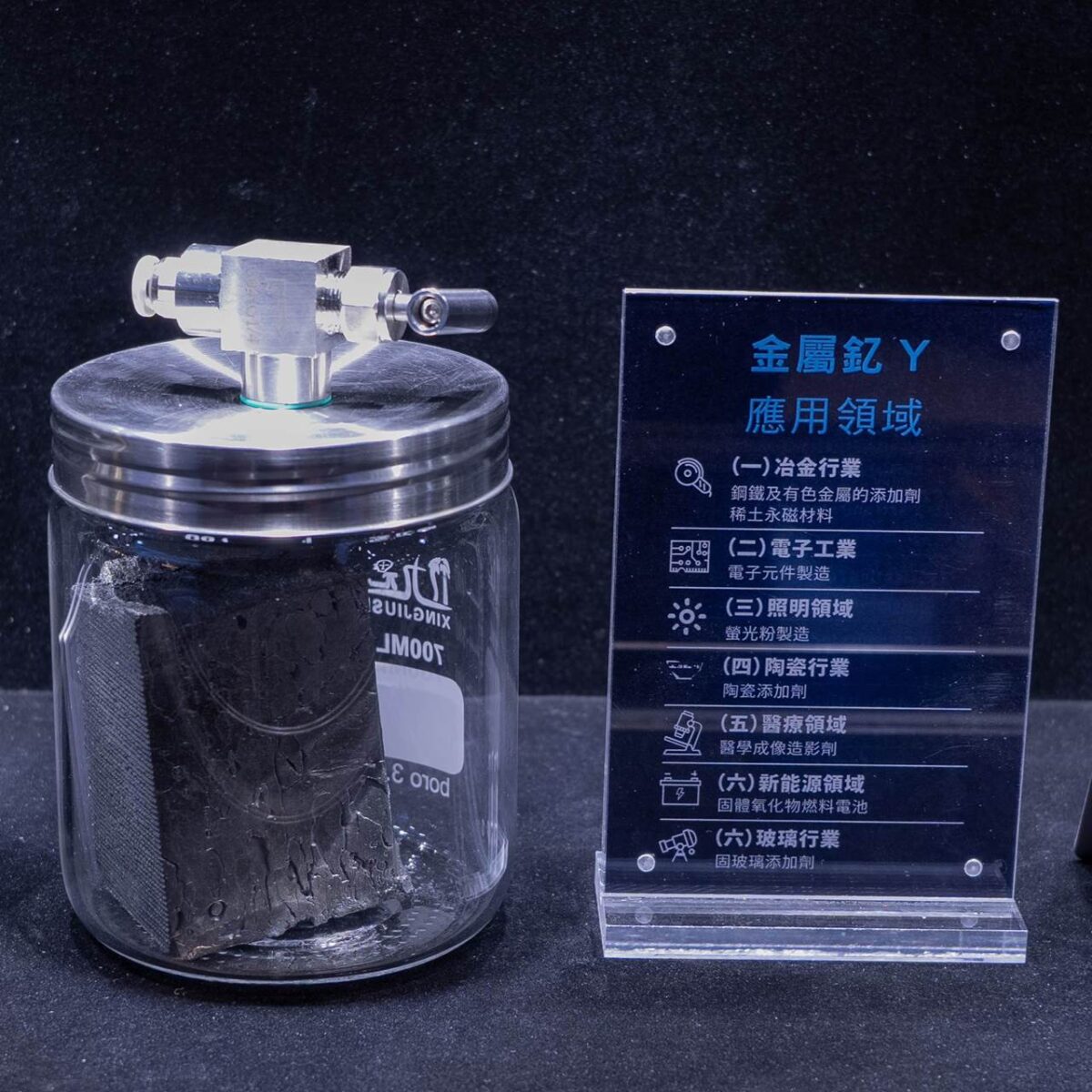

Electronic Industry

Electronic Component Manufacturing

In the manufacture of some electronic components, such as electronic transformers and inductors, gadolinium-iron alloy can be used as raw material to further process and extract gadolinium elements for the manufacture of gadolinium-containing electronic components. Gadolinium-containing electronic components have unique electromagnetic properties, such as high magnetic permeability and low magnetic loss, which can meet the needs of modern electronic equipment for continuous miniaturization and high-performance development. They are widely used in many electronic devices such as smartphones, computers, and communication base stations.

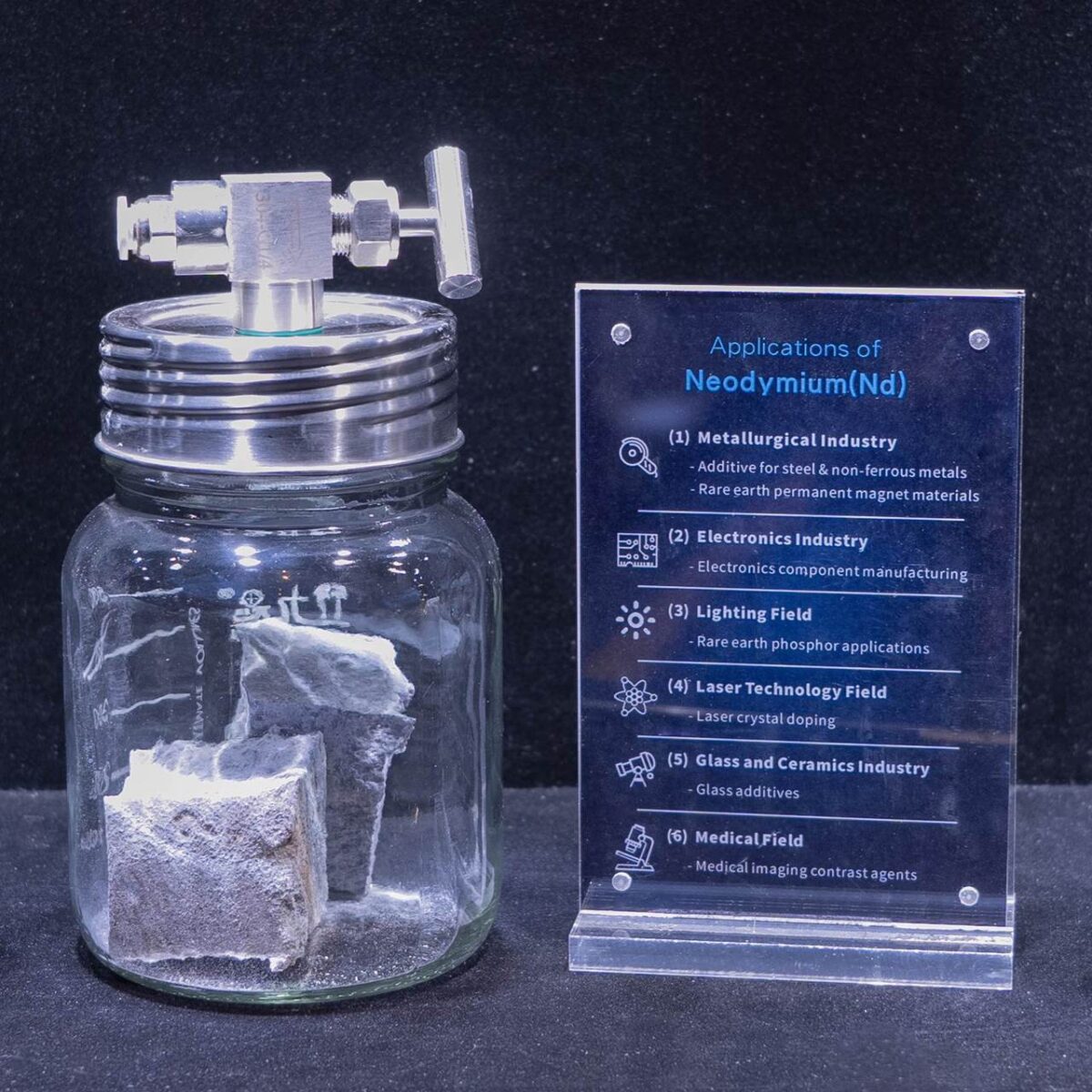

Steel Industry

Improving Steel Performance

Adding an appropriate amount of gadolinium-iron alloy to the production of alloy steel and stainless steel, the gadolinium element will combine with carbon, nitrogen, and other elements in the steel to form fine and dispersed compounds. These compounds can effectively hinder the dislocation movement of steel during the force process, thereby significantly improving the strength and toughness of steel. When steel is subjected to large loads and impact, it can maintain high strength and is not easy to break, expanding the application range of steel and is commonly used in the production of high-quality steel in fields such as construction and mechanical manufacturing.

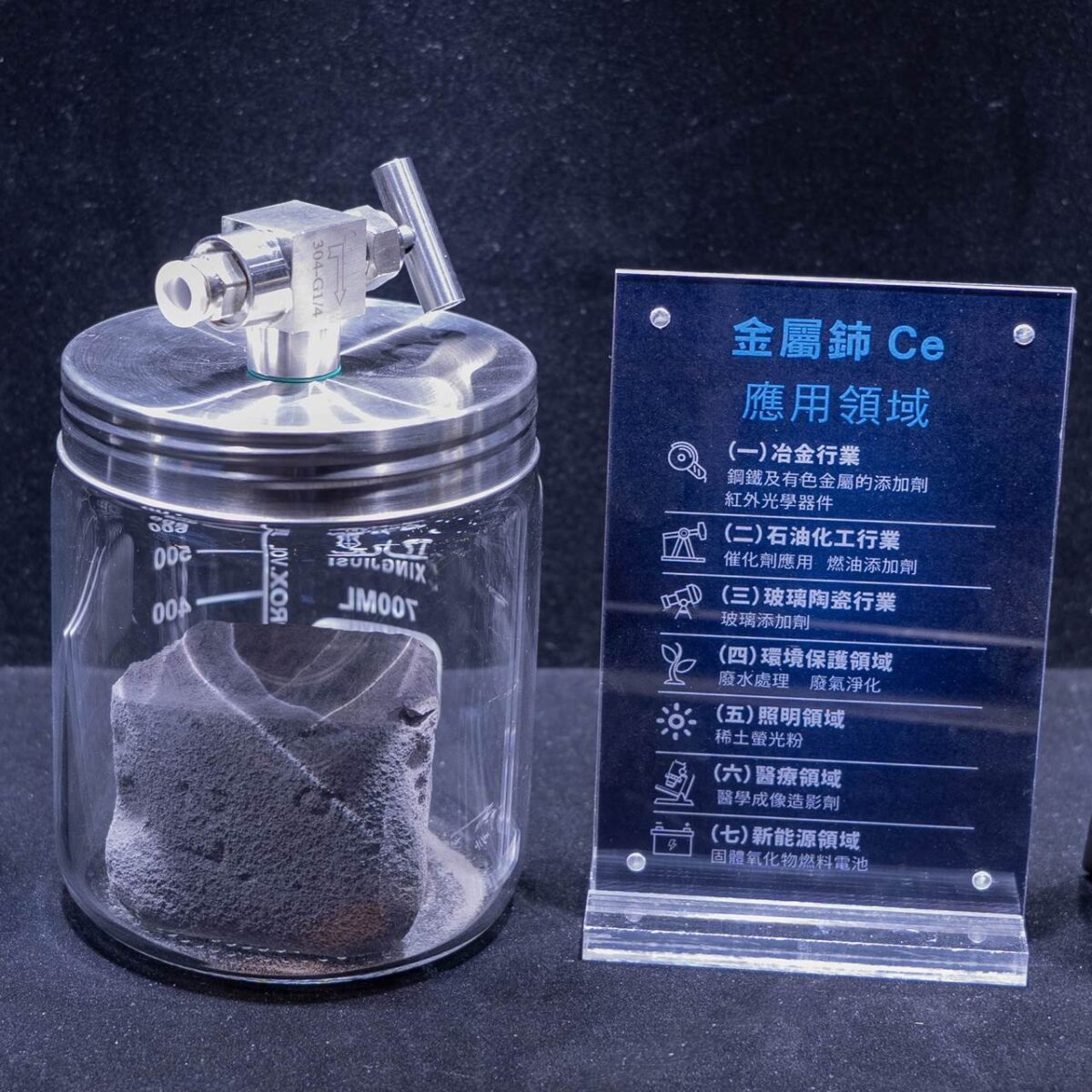

Medical Field

Magnetic Resonance Imaging (MRI) Contrast Agent

The gadolinium element in gadolinium-iron alloy is a commonly used component of MRI contrast agents. After special treatment of gadolinium-iron alloy to make gadolinium-containing contrast agents, when injected into the human body, the gadolinium element can change the relaxation time of surrounding tissues, making the diseased tissue and normal tissue form a more obvious contrast on the MRI image, which is convenient for doctors to diagnose diseases more accurately, such as detecting tumors, brain diseases, etc. It plays an indispensable role in modern medical diagnosis.