Non-Edible Chemical Ice Powder

Appearance

Non-edible chemical ice powder typically appears as a fine, uniform powder in white, off-white, or slightly colored forms, with no significant large particles or clumps. It has good flowability, making it easy to measure and mix accurately for various applications.

Particle Size and Density

Particle sizes vary, with most products falling within the micrometer range. However, some products can be finer (nanometer level) or coarser depending on the production process and application requirements. The density is moderate, making the powder lightweight and easy to store and transport. It maintains a stable physical state during normal packaging and handling, without easily separating or compacting.

Solubility and Hygroscopicity

Solubility varies depending on the components. Some powders can dissolve or swell in specific solvents (such as certain organic solvents or acid/base solutions), while most are poorly soluble in water and common solvents, maintaining their powdered state. However, these powders have a certain degree of hygroscopicity. Upon contact with moisture, they begin to absorb water and gradually react, laying the foundation for subsequent gel formation or other functional applications. The speed and extent of water absorption vary.

Stability and Reactivity

Non-edible chemical ice powder is chemically stable under normal temperature and pressure conditions and in typical storage environments. It does not readily react with oxygen or moisture in the air. However, different components can exhibit specific reactivities when exposed to certain chemicals. For example, polymer powders with active functional groups can rapidly cross-link to form gels in the presence of suitable cross-linking agents. Inorganic components containing metal ions may undergo chemical reactions when exposed to strong acids or bases, altering their structural properties. This characteristic allows them to achieve diverse functions through interactions with different chemicals.

Modifiability and Functional Expansion

The powder can be modified through various chemical methods. For example, grafting specific functional groups onto its surface can improve its compatibility with other materials or enhance properties such as adsorption and catalysis. Alternatively, doping with other functional elements, such as conductive materials, can create powders with specific properties like electrical conductivity. This flexibility enables the powder to meet the unique performance requirements of various industrial and research applications, expanding its scope of use.

Gel Formation Capability

The most critical property of non-edible chemical ice powder is its ability to form gels under suitable conditions (such as the addition of specific solvents, temperature adjustment, or the use of initiators). The resulting gel has a certain strength, elasticity, and stability, making it suitable for simulating different material environments, carrying specific substances, or achieving specific physical and chemical functions. This characteristic makes it widely applicable in numerous fields.

Adsorption Capability

Some non-edible chemical ice powders have strong adsorption capabilities due to their unique component structures and large specific surface areas (especially those containing porous inorganic components or adsorptive functional groups in polymers). They can absorb harmful components from gases (such as sulfur dioxide and nitrogen oxides in industrial exhaust) and impurities from liquids (such as heavy metals and organic pollutants in water). As a result, they play an important role in environmental protection as adsorbents for purification.

Controlled Release

In the preparation of agents like pharmaceuticals and fertilizers, the powder can be used to create encapsulated gel structures that release active ingredients at a predetermined rate. For pharmaceuticals, this allows for continuous and stable drug release in the body or at the target site, reducing the frequency of dosing. For fertilizers, it provides a steady supply of nutrients according to the plant growth cycle, improving utilization efficiency and avoiding waste and environmental problems caused by excessive one-time application. This demonstrates significant application value.

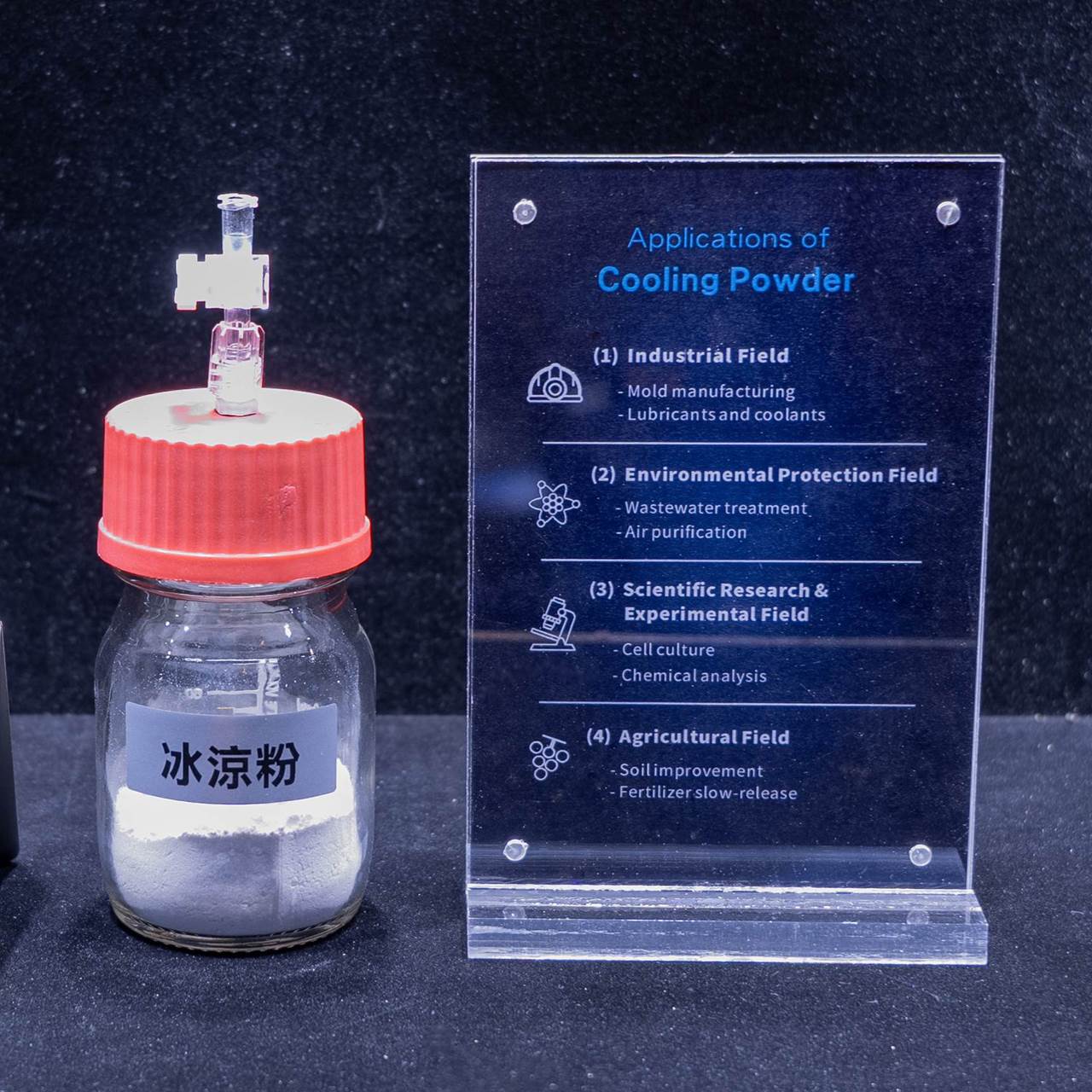

Industrial Field

Sealing and Filling Materials

In industrial scenarios such as mechanical manufacturing and pipeline installation, the powder can be used as a sealing material. Mixing the powder with an appropriate solvent to form a paste or gel, it can be applied to connections in equipment or pipe joints. Once gelled, it provides an effective seal to prevent liquid or gas leakage. It is commonly used in chemical pipelines and automotive engine components for sealing. Additionally, it can fill small gaps and holes, making component surfaces smoother and enhancing overall structural stability. It is often used in casting and mold-making processes to improve product quality and precision.

Lubrication and Friction Reduction

Adding the powder to lubricants or greases can form a gel-like protective film on friction surfaces. This reduces the friction coefficient and minimizes wear between mechanical components, extending equipment lifespan. It is effective in high-speed, heavy-load machinery (such as machine tool spindles and gear transmission devices), improving operational efficiency and reliability while reducing maintenance costs.

Environmental Field

Wastewater Treatment

As an efficient adsorbent in wastewater treatment, the powder can adsorb heavy metals (such as mercury, cadmium, lead, chromium), organic pollutants (such as dyes, pesticides, petroleum products), and suspended solids from water. After subsequent treatment steps like sedimentation and filtration, it effectively purifies wastewater to meet discharge standards. It can also be fixed on specific carriers to form adsorption columns for continuous wastewater treatment, improving efficiency and automation in industrial and domestic wastewater treatment.

Air Purification

Used in air purification materials, the powder can be mixed with binders to form filter meshes or sheets, or directly filled into air purification devices. It absorbs harmful gases (such as formaldehyde, benzene, sulfur dioxide, nitrogen oxides), fine particulate matter (PM2.5, PM10), and microorganisms from the air, improving air quality and protecting living and working environments. It is particularly suitable for use in indoor air purifiers and industrial ventilation systems.

Research and Experimental Field

Biomedical Research

In biomedical research projects such as cell culture and tissue engineering, the powder can be used to create biocompatible gel scaffolds that provide a three-dimensional support environment for cell growth and differentiation. This mimics the extracellular matrix in vivo, allowing researchers to observe cell behavior, interactions, and drug effects, advancing fields like regenerative medicine and pharmacology. Additionally, in the development of biosensors, its gel properties and modifiability can be used to immobilize biomolecular recognition elements for sensitive detection of specific biomarkers.

Materials Science Research

In the development of new materials, the powder can be used as a model material or functional additive. For example, by altering the components and preparation conditions of the powder, researchers can study the formation mechanisms, mechanical properties, and thermal properties of gel materials. This provides theoretical and experimental basis for developing high-performance gel-based materials. Alternatively, adding the powder to other matrix materials can introduce new properties (such as adsorption or controlled release), exploring innovative applications in materials science.

Agricultural Field

Soil Improvement

When added to soil, non-edible chemical ice powder can improve soil structure by increasing porosity and water retention, making the soil more loose and breathable. This is beneficial for plant root growth. Its adsorption properties can also capture harmful substances in the soil, such as pesticide residues and heavy metals, reducing their impact on plant growth and improving soil fertility. It is particularly useful for remediating contaminated soils and improving poor-quality soils, supporting sustainable agricultural development.

Controlled Release of Fertilizers and Pesticides

The powder can be used to create controlled-release fertilizers and pesticides. By encapsulating the active ingredients of fertilizers or pesticide active components within the gel structure formed by the powder, it can release the active substances gradually according to the plant growth stage or pest control schedule. This improves the utilization efficiency of fertilizers and pesticides, reduces environmental pollution and resource waste caused by excessive use, and aligns with the concept of modern green agriculture.

Chemical Industry Field

Catalyst Carrier

The powder can serve as a catalyst carrier by loading catalytically active substances onto the surface or within the gel structure formed by the powder. Its large specific surface area and porous structure can increase the dispersion of catalysts and the number of active sites, thereby enhancing catalyst activity and selectivity. This allows chemical reactions to proceed more efficiently. It has potential application value in numerous chemical production processes, such as petroleum refining and organic synthesis, helping to improve product yield and quality while reducing production costs.

Coating Additive

When added to various coatings, the powder can improve the rheological properties of the coating. This ensures better leveling and anti-sagging properties during application, resulting in a uniform and smooth coating. Additionally, it can impart special functions to the coating, such as odor absorption or negative ion release, increasing the added value of the coating and expanding its application range. It can be used in different environments and applications, such as architectural coatings and industrial anti-corrosion coatings.